Differences Between Gasoline and Diesel Nozzles

Don't Judge a Nozzle by Its Size: Exploring the Science Behind Gas Pump Design

In the fast-paced rhythm of modern life, a trip to the gas station is a routine chore. We grab a gas pump nozzle, insert it into the fuel tank, and wait for the fill-up to complete. Yet, have you ever considered the sophisticated engineering hidden within this simple, everyday action? For families or companies operating a fleet of mixed-fuel vehicles, the distinction between a gasoline nozzle and a diesel nozzle is more than just a different color on the handle. It's a meticulously crafted physical barrier designed by engineers to prevent one of the most costly and catastrophic mistakes a driver can make: misfueling.

This article will take a deep dive into the design intricacies of Fuel nozzles, gas dispenser pumps, and the critical differences between a diesel nozzle and a gasoline nozzle. We'll explore why these seemingly minor variations in size, color, and internal mechanics are crucial safeguards that protect millions of vehicles and their drivers on the road.

The Great Size Debate: A Physical Barrier You Can't Bypass

The most striking and fundamental difference between a diesel nozzle and a gasoline nozzle is their diameter. This is no accident; it's the result of a core engineering principle known as "poka-yoke," or mistake-proofing.

Across most of the world, industry standards dictate the specific dimensions of these gas nozzles:

-

The tip of a gasoline nozzle is typically narrower, around 13/16 of an inch (approximately 20.6 mm).

-

The tip of a diesel nozzle is slightly larger, measuring around 15/16 of an inch (approximately 23.8 mm).

This small size difference of just a few millimeters creates an effective physical incompatibility. When a driver attempts to insert a larger diesel nozzle into the smaller filler neck of a gasoline-powered car, it simply won't fit. This mechanical roadblock serves as a vital first line of defense, dramatically reducing the risk of a driver putting diesel into a gas car, as they are alerted to the error by the physical resistance.

However, this physical barrier is not foolproof in the opposite scenario. Because a diesel car's filler neck must accommodate the larger diesel nozzle, its opening is also wider. This means that a smaller gasoline nozzle can be easily inserted into a diesel car's tank. This is precisely why drivers putting gasoline into a diesel vehicle is a far more common and, as we'll discuss, a much more damaging mistake.

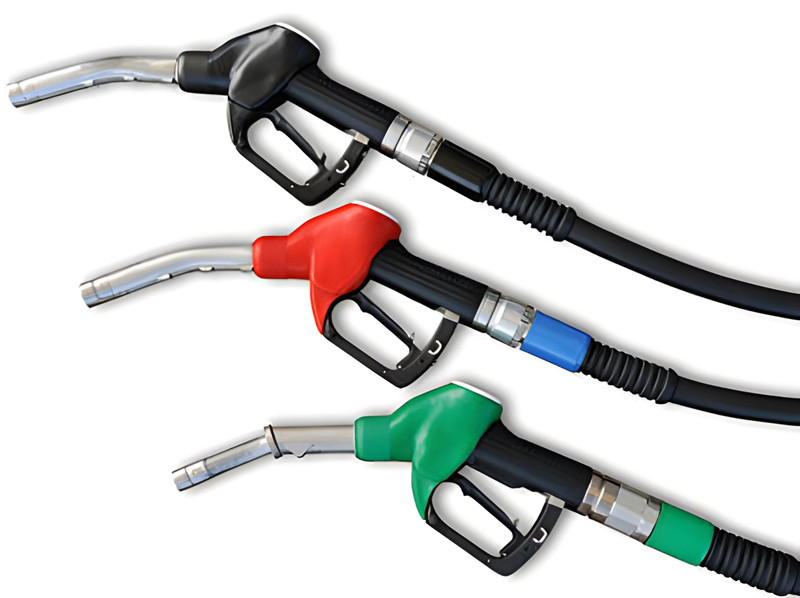

Color and Flow Rate: A Dual-Layered Warning System

Beyond size, color coding on a gas pump nozzle is another essential safety feature. Its purpose is to provide an immediate visual cue before a driver even begins the fueling process, reducing the chance of a careless error.

-

The standard color for a diesel nozzle is typically green.

-

Gasoline nozzles are most often coded in colors like black, red, or blue.

While this color scheme is a widely adopted industry convention, it is not universal. Different brands and regions may use their own specific color schemes, which is why it is always essential to not rely solely on color. The labels on the gas dispenser pump itself, which clearly indicate the fuel type, are the ultimate and most reliable source of truth.

Furthermore, the internal design of a gas pump nozzle differs to account for the unique physical properties of each fuel. Diesel is denser and more viscous than gasoline. To ensure an efficient and timely fill-up, diesel nozzles are engineered to deliver fuel at a much higher flow rate. This is particularly noticeable at truck stops, where larger 1-inch and even 1.5-inch gas nozzles can dispense fuel at a staggering rate of up to 200 liters per minute, catering to the enormous fuel tanks of commercial vehicles.

The Technology Within: A Leap from Simple Hardware to Smart Safeguards

When discussing Fuel nozzles, one of the most critical safety features is the automatic shut-off mechanism. This technology is a standard feature on all modern gas dispenser pumps and is a testament to clever engineering.

Located at the very tip of the gas nozzle is a small, vacuum-sensing hole. As fuel fills the tank, the liquid level rises. Once the rising fuel level covers this small hole, it triggers a change in air pressure. This pressure change creates a negative signal that is instantly relayed to the nozzle’s internal mechanical system, causing the trigger to spring back and immediately stop the flow of fuel. This ingenious design prevents fuel spills and ensures a clean, safe, and precise fueling experience.

In the era of automation and intelligent technology, gas nozzles and gas dispenser pumps are continuing to evolve. While the core physical design remains paramount, new technologies are adding more layers of security. Some advanced systems now integrate Radio-Frequency Identification (RFID) technology. When a vehicle enters the fueling area, the system automatically identifies the vehicle and its required fuel type, displaying only the correct option on the gas dispenser pump screen. This kind of technology is the foundation for future unmanned gas stations and further minimizes the potential for human error.

The Costly Consequence of Misfueling

The financial and mechanical consequences of misfueling are severe. Understanding the reasons behind the nozzle design is to understand the potential damage.

-

Gasoline is a highly volatile, low-lubricity fuel that ignites via a spark plug.

-

Diesel is a low-volatility, high-lubricity fuel that ignites under high compression.

When you put gasoline into a diesel engine, the gasoline’s lack of lubricating properties rapidly strips the protective layer from the high-pressure Fuel pump and injectors. This leads to friction, premature wear, and a complete failure of the fuel system. Conversely, putting diesel into a gasoline engine is less common due to the nozzle size, but if it happens, the engine will likely fail to start. If it does start, the diesel will not ignite properly, leading to significant smoking and a rapid engine shutdown, causing damage to the exhaust system.

Ultimately, regardless of how well-designed the gas pump nozzle is, the driver's diligence remains the final and most important safeguard. Taking a few seconds to verify the label on the pump, check the nozzle color, and cross-reference it with the fuel type indicated on your car's fuel door is the simplest and most effective way to prevent an expensive mistake.

Conclusion: A Masterclass in Thoughtful Engineering

From the subtle size difference to the specific color coding and the intricate automatic shut-off mechanism, every aspect of a fuel nozzle reflects a deep consideration for safety and efficiency. These design choices are not arbitrary; they are deliberate solutions to a potential hazard. By providing clear physical and visual cues, the design aims to guide users intuitively and reduce the likelihood of human error in a potentially dangerous environment.

So, the next time you pick up a gas dispenser pump, take a moment to appreciate the small details. You'll find that this everyday tool is a testament to thoughtful engineering, designed with your safety in mind.