Fuel Nozzle Maintenance: Key Points to Consider

Fuel nozzle Maintenance: The Frontline Hero of Your Gas Station

At a gas station, a lot of equipment works behind the scenes to get fuel from the underground storage tanks to a vehicle. But there’s one piece of equipment that every customer interacts with directly: the Fuel nozzle. It's the "frontline hero" of your operation, and its performance and safety directly impact fueling efficiency, customer experience, and the overall security of your gas station.

A well-maintained fuel nozzle is more than just a tool—it’s a symbol of your commitment to safety and quality. A faulty nozzle can lead to spills, inaccurate readings, and even fire hazards, all of which can damage your reputation and lead to costly repairs. This article provides a comprehensive guide to fuel nozzle maintenance, detailing the key checks and procedures to keep your equipment in top condition. We’ll cover everything from the basic gas nozzle to the more specialized diesel pump nozzle and fuel tank nozzle.

1. Daily Checks: Spotting Potential Problems

Regular, daily inspections are your first line of defense against potential problems. These simple checks can help you identify issues before they become serious safety hazards.

External Inspection

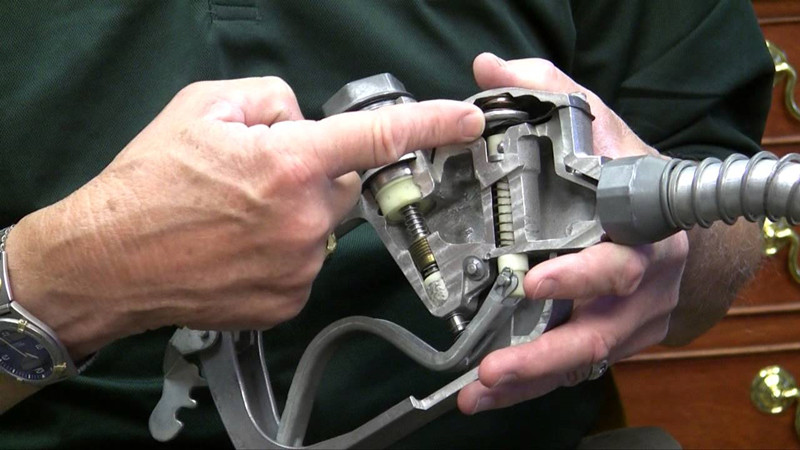

The physical condition of your fuel nozzle can tell you a lot. A quick visual check can reveal signs of wear and tear that might otherwise go unnoticed.

-

Focus: Check the exterior of the nozzle for physical damage, such as cracks, dents, or corrosion. The body, handle, and spout should be free of any noticeable flaws.

-

Action: Take a moment to inspect each gas nozzle and diesel pump nozzle as part of your daily routine. Look for any signs of impact damage, which could compromise the nozzle's internal components and seals.

Seal Integrity

Leaks are a major safety and environmental hazard. Ensuring the seals on your fuel nozzle are intact is one of the most important checks you can perform.

-

Focus: Check for signs of aging or damage on the seals around the connectors and spout. A worn-out seal is a common cause of fuel leaks and can lead to inaccurate fuel dispensing.

-

Action: After each use, perform a quick check of the spout on the fuel tank nozzle for any dripping. If you notice any consistent dripping, it’s a clear sign that the seals need to be replaced.

Functional Test

The automatic shut-off and locking mechanisms are essential safety features. A malfunctioning shut-off can lead to fuel spills, while a faulty lock can create a hands-on fueling risk.

-

Focus: Test the nozzle's automatic shut-off function and the locking mechanism. The nozzle should be able to stop dispensing fuel on its own when the tank is full.

-

Action: During a fueling session, simulate a full tank by partially pulling the nozzle out of the fill neck to test if the nozzle shuts off automatically. If it doesn't, take the nozzle out of service immediately and arrange for maintenance.

2. In-Depth Maintenance: Ensuring Reliable Core Functions

While daily checks are great for catching obvious issues, a deeper, more detailed maintenance plan is needed to ensure the long-term reliability of your fueling equipment.

Spout Cleaning and Inspection

A dirty spout can restrict fuel flow and affect the accuracy of your readings.

-

Focus: Clean any dirt, grime, or foreign objects from around the nozzle spout to ensure smooth fuel flow.

-

Action: Regularly clean the spout with a soft cloth. This is especially important for the diesel pump nozzle, which has a larger spout diameter that is more susceptible to debris buildup.

Hose and Connector Maintenance

The hose connecting the nozzle to the gasoline dispenser is under constant stress. Maintaining it is key to preventing leaks and ensuring smooth operation.

-

Focus: Check the hose for cracks, kinks, or signs of wear. These can cause leaks and restrict fuel flow.

-

Action: Inspect the connections between the hose and both the gasoline dispenser and the gas nozzle. Make sure the connections are tight and secure. Loose connections are a common source of leaks and safety hazards.

Flow Rate Calibration and Performance Testing

Accuracy is everything in the fueling business. An inaccurate pump can lead to customer disputes and lost revenue.

-

Focus: Ensure that the nozzle’s Flow meter is accurate to prevent measurement disputes.

-

Action: Regularly calibrate the nozzle with the Flow meter on the gasoline dispenser to ensure the dispensed volume matches the volume displayed on the screen.

3. Maintenance Tips for Different Nozzle Types

Not all nozzles are created equal. Different fuel types and applications require specific maintenance considerations.

Gasoline Nozzles

-

Maintenance Focus: Gasoline is highly volatile, so special attention should be paid to the maintenance of the vapor recovery function, if equipped. Check that the vapor recovery channel on the vapour recovery nozzle is unobstructed.

Diesel Pump Nozzles

-

Maintenance Focus: Diesel fuel is thicker than gasoline and can turn into a waxy gel in cold temperatures. Pay attention to any sediment buildup inside the nozzle that could be a result of this.

Fuel Tank Nozzles

-

Maintenance Focus: These nozzles, which are used to fill underground storage tanks, require special attention to their large-flow sealing to prevent spills and environmental contamination.

Conclusion: Safety and Efficiency Start with the Details

Routine maintenance of your fuel nozzle may seem like a small detail, but it’s a critical part of ensuring your gas station operates efficiently and safely. A well-maintained fuel nozzle not only extends the life of your equipment but also builds customer trust and prevents potential safety risks and financial losses.

A robust maintenance program is key to your success. Our professional fueling equipment is not only high-performing but also designed for ease of maintenance. Contact us today to learn more about our products and get expert advice on how to keep your gas station safe and running smoothly.