Why your dispensers and submersible pumps need seasonal fuel adjustments?

Have you ever wondered if the fuel you pump into your car in the dead of winter is the same as what you used on a hot summer day? The answer might surprise you: it’s not. The fuel in your tank changes with the seasons, and this isn't just a marketing gimmick—it’s a critical, carefully engineered adjustment. This seasonal change is a matter of chemistry and physics, designed to ensure your vehicle runs smoothly and safely regardless of the temperature.

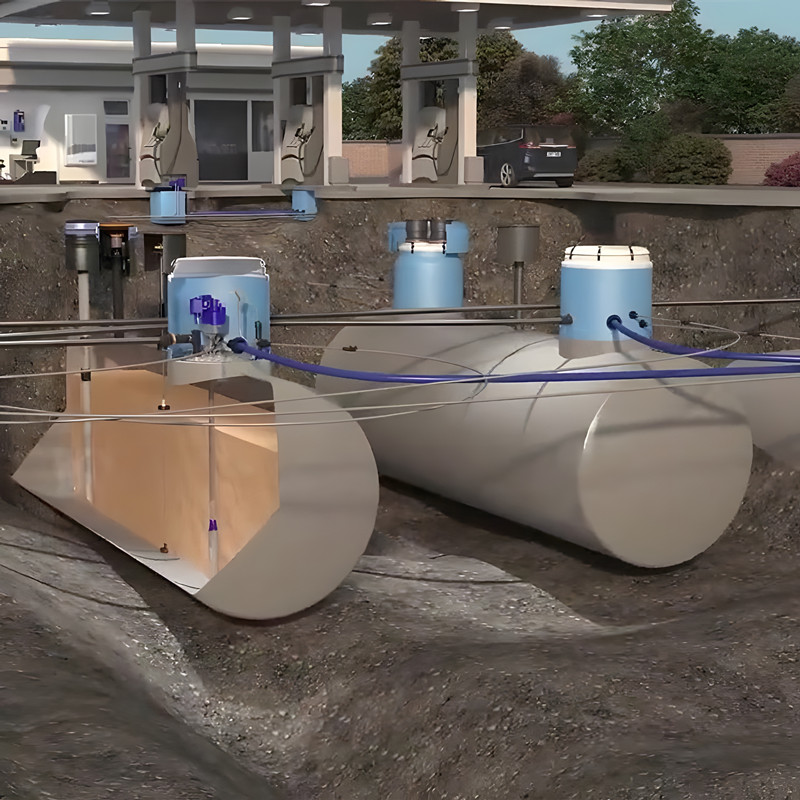

So, why do gas stations need to adjust their fuel formulas with the seasons? And what does this mean for the essential equipment you rely on every day, from the petrol pump dispenser to the petroleum pumps humming quietly underground? As a leader in fueling equipment manufacturing, we're here to explain the science behind seasonal fuels and the crucial maintenance for forecourt diesel pumps for petrol stations and other equipment that keeps your station running year-round.

1. Winter vs. Summer Blend Fuels: The Core Differences

The fundamental difference between winter and summer blend fuels lies in their volatility, which is measured by a property called Reid Vapor Pressure (RVP). This refers to how easily the fuel evaporates.

Winter Blend Fuel Characteristics:

-

Higher Volatility: Winter fuel has a higher RVP. This is by design. In cold weather, higher volatility helps the fuel evaporate more easily, ensuring that your engine starts without a hitch and runs smoothly.

-

Anti-Gelling Agents: For diesel specifically, winter blends contain additives to prevent the fuel from "gelling" or turning to a waxy solid. This is crucial for forecourt diesel pumps, as gelling can clog fuel filters and lines, leading to pump failure.

-

Ethanol's Role: Ethanol is also a key component in winter gasoline, as it acts as a de-icing agent, preventing water in the fuel lines from freezing.

Summer Blend Fuel Characteristics:

-

Lower Volatility: Summer fuel has a lower RVP. In hot temperatures, this lower volatility is essential to prevent the fuel from evaporating too quickly.

-

Prevents Vapor Lock: High volatility in hot weather can cause "vapor lock," where fuel turns into a gas in the lines, disrupting fuel flow and causing engine stalling. Low-RVP summer blends prevent this.

-

Environmental Compliance: Lower volatility also means fewer evaporative emissions, which is a key requirement for meeting stricter summer air quality regulations.

2. How Seasonal Fuel Changes Impact Your Station's Equipment

The shift from one blend to another places a unique set of demands on your fueling equipment. Each piece of the system, from the petrol pump dispenser at the forecourt to the petroleum chemical industry submersible pump buried beneath it, must be ready to handle these seasonal changes.

The Petrol Pump Dispenser:

-

Winter Challenges: The higher volatility of winter fuel means it's more fluid. This can put stress on seals and gaskets within the petrol pump dispenser, requiring careful inspection to prevent leaks.

-

Summer Challenges: The lower volatility but higher density of summer fuel can impact flow rates. More importantly, the high ambient temperatures require a properly functioning vapour recovery nozzle to prevent evaporative emissions and ensure a safe, compliant refueling environment.

The Submersible Pump:

-

Winter Challenges: For diesel, the risk of gelling in cold weather is a major concern. If the fuel in the underground tank starts to gel, it can put a massive strain on the petroleum chemical industry submersible pump, leading to pump failure. For this reason, many submersible pumps for diesel tanks come equipped with heating elements.

-

Summer Challenges: Higher temperatures can cause the submersible pump to work harder, increasing the risk of overheating and premature wear. It's vital to ensure proper tank ventilation to prevent excessive pressure buildup.

Forecourt Diesel Pumps Maintenance Focus:

-

Winter: The primary focus is on preventing cold-related failures. This includes checking fuel filters for signs of paraffin wax buildup, ensuring anti-gelling additives are effectively blended, and verifying that the pump's internal heating systems are operational.

-

Summer: The focus shifts to combating heat and pressure. This involves checking for vapor leaks, ensuring the maintenance for forecourt diesel pumps for petrol stations includes cleaning vapor recovery lines, and monitoring pump temperatures to prevent overheating.

3. A Seasonal Maintenance Guide for Fueling Equipment

To ensure seamless operation and regulatory compliance, a proactive, seasonal maintenance plan is essential.

Winter Maintenance Checklist:

-

Forecourt Diesel Pumps: Inspect and replace fuel filters more frequently to combat wax deposits.

-

Submersible Pump: Verify that the pump’s heating element is functional and test its activation threshold.

-

Petrol Pump Dispenser: Test the dispenser’s performance in cold temperatures and check for any leaks in seals and hoses due to reduced material flexibility.

Summer Maintenance Checklist:

-

Vapour Recovery System: Clean the vapour recovery nozzle and lines to ensure they are free of blockages and can effectively capture fumes.

-

Tank Ventilation: Check the tank vents to ensure they are clear and operating correctly to prevent excessive pressure from building up.

-

Submersible Pump: Monitor the pump’s operating temperature to prevent overheating and check the flow rate to ensure it’s not being affected by reduced fuel volatility.

4. How the Petroleum Industry Responds to Seasonal Changes

This seasonal switch isn't a last-minute decision; it's a carefully orchestrated process that involves the entire supply chain.

-

Refinery Adjustments: Refineries adjust their blending processes months in advance. They change the ratios of different hydrocarbons in the fuel to meet RVP targets for each season.

-

Storage Tank Management: Gas stations work closely with their suppliers to manage the transition. There is typically a period where both summer and winter blends are present in the supply chain, and stations must ensure their underground storage tanks are ready for the new blend.

-

Role of Chemical Additives: In addition to blending, chemical additives like anti-gelling agents for winter diesel and antioxidants for summer gasoline are crucial. These additives are injected into the fuel to fine-tune its performance and protect vehicle engines.

5. FAQ

Q: Can misfueling with the wrong seasonal blend damage my vehicle?

A: Yes, it can. Using summer blend in the winter can lead to poor cold starting, and in the case of diesel, a gelling risk. Using winter blend in the summer can cause vapor lock and poor performance. While it might not cause immediate catastrophic failure, it will certainly impact performance and can lead to long-term issues.

Q: Do gas stations need to replace equipment for seasonal fuel changes?

A: No, not typically. Modern equipment is designed to handle the full range of fuel properties. However, regular and seasonal-specific maintenance for forecourt diesel pumps for petrol stations and other equipment is absolutely essential to ensure reliable operation.

Q: What's the difference in ethanol gasoline during different seasons?

A: The concentration of ethanol remains the same, but the RVP of the base gasoline is adjusted. Ethanol itself is a volatile component, so its presence affects the overall RVP. Refiners must account for this when creating both summer and winter blends.

Conclusion

The difference between winter and summer blend fuel is a testament to the sophisticated engineering and meticulous planning that underpins our modern world. It’s a silent, behind-the-scenes process that ensures your car starts reliably on the coldest morning and runs smoothly on the hottest day.

This intricate system, however, is only as strong as its weakest link. The petrol pump dispenser, the submersible pump, and all the other petroleum pumps at your station are the critical last mile of this journey. Their robust design and proper maintenance for forecourt diesel pumps for petrol stations are what guarantee a safe and seamless experience for every customer, all year round.