Is Pipeline Modification Necessary for Installing an LC Positive Displacement Flow Meter?

Is Pipeline Modification Necessary for Installing an LC Positive Displacement Flow meter?

In industries such as marine, petrochemical, and energy, flow measurement is a critical component for ensuring the efficiency and safety of fuel management systems. The LC Positive Displacement Flow meter (often referred to as a PD flow meter or LC Meter) is widely favored for its high accuracy and reliability. However, a common concern among users during the selection process is whether installing such a flow meter requires modifications to existing fuel pipelines. This article provides an in-depth analysis from technical principles, installation types, key implementation points, and industry practices to offer practical guidance for professionals.

1. Working Principle and Installation Characteristics of Positive Displacement Flow Meters

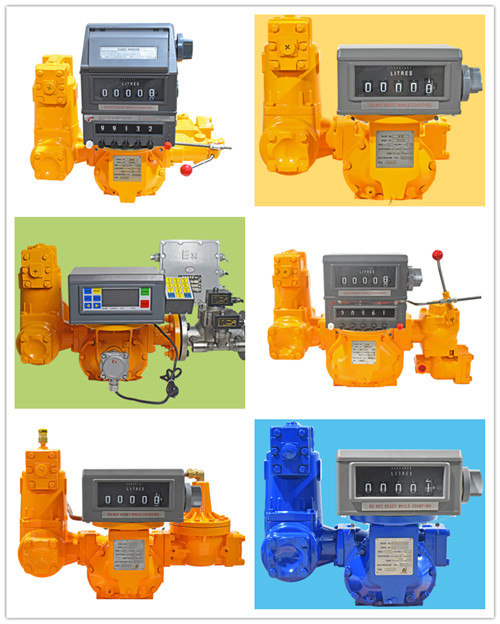

Positive Displacement (PD) Flow Meters calculate flow rate by measuring the number of times a fluid fills and discharges from a fixed volume within the meter’s chamber. As a renowned brand in this field, LC Meter typically employs gears, pistons, or rotating vanes to accurately measure high-viscosity fluids such as fuel and lubricating oil. This high precision makes it the preferred choice for critical applications like fuel trade settlement and energy consumption monitoring.

However, the installation method of a PD flow meter directly determines its compatibility with existing pipeline systems. Structurally, LC Meters are in-line flow meters, meaning they must be connected directly in series within the main pipeline, unlike clamp-on flow meters that require no pipeline cutting. Therefore, in most cases, modification of the existing fuel pipeline is necessary when installing an LC Positive Displacement Flow Meter. The core of such modification involves integrating the flow meter seamlessly into the pipeline via flanged or threaded connections, ensuring both sealing integrity and fluid continuity.

2. Why Pipeline Modification Is the Norm: The Technical Necessity of In-Line Installation

-

Accuracy and Flow Stability Requirements

PD flow meters are highly sensitive to fluid flow profiles. If installed via non-standard methods such as direct welding or bypass installation, turbulence, air bubbles, or particle sedimentation may occur, significantly affecting measurement accuracy. By cutting the existing pipeline and installing standard flanged or threaded connections, the required straight pipe lengths upstream and downstream (typically 10D and 5D, respectively, where D is the pipe diameter) can be ensured, stabilizing the flow profile and minimizing measurement errors. -

Sealing and Safety Considerations

Fuel pipelines often transport flammable, high-pressure media, where any leakage could lead to serious safety incidents. LC Meters are designed to comply with international standards such as ASME and ISO, and their flanged or threaded connections undergo rigorous pressure testing. Professional modification ensures that the sealing grade (e.g., PN16, ANSI 150) matches the existing pipeline, preventing leakage risks during long-term operation. -

Ease of Maintenance and Replacement

Although in-line installation requires initial modification, it facilitates future calibration or replacement. For example, PD flow meters used in fuel purification systems or engine supply lines may require periodic maintenance. Flanged connections allow for quick disassembly and reassembly, reducing downtime.

3. Key Steps and Professional Recommendations for Pipeline Modification

Although modification is generally required, the extent of changes depends on the existing pipeline conditions. Below is a typical implementation process:

-

Pre-Installation Assessment and Design

-

Pipeline Audit: Inspect the material, diameter, pressure rating, and corrosion status of the existing pipeline. If the pipeline is severely aged, partial section replacement may be necessary.

-

Parameter Matching: Determine the flange standard (e.g., DIN, JIS) or thread specification (e.g., NPT, BSP) based on the flow meter model (e.g., LC Model series).

-

Space Planning: Ensure the installation location provides sufficient space for wiring and maintenance.

-

-

Cutting and Connection Installation

-

A professional marine technician or pipeline engineer should cut the pipeline using specialized tools and deburr the cut edges.

-

Welding or thread sealing must use fuel-resistant materials (e.g., PTFE tape) to avoid chemical corrosion.

-

Install isolation valves upstream and downstream to facilitate flow meter maintenance.

-

-

System Testing and Verification

-

After installation, conduct pressure testing (e.g., holding at 1.5 times the working pressure) and leakage checks.

-

Validate the reading stability of the LC Meter through simulated or actual flow conditions, adjusting the meter factor if necessary.

-

4. Exceptions: When Might Modification Be Unnecessary?

In rare scenarios, installing a PD flow meter may not require extensive modification:

-

Pre-Existing Interfaces: If the pipeline design already includes flanged interfaces or quick connectors, the LC Meter can be directly adapted.

-

Bypass Installation: For large-diameter pipelines, a bypass configuration can be used, where a smaller PD flow meter is installed on a branch line. However, the impact of bypass valve accuracy on overall measurement must be considered.

-

Modular Subsystem Replacement: For instance, when replacing an entire fuel measurement unit, the new unit may already integrate a flow meter, requiring only connection to the main pipeline.

These exceptions, however, require rigorous technical evaluation and often still involve minor adjustments.

5. Industry Practices and Common Misconceptions

Case studies demonstrate that neglecting professional modification can lead to severe consequences. For example, a marine company attempting to reduce costs by non-standard welding instead of cutting the pipeline for an LC Meter installation resulted in:

-

Gear deformation due to welding stress, causing measurement errors exceeding 5%;

-

Minor leaks at the connection points leading to fuel loss;

-

Ultimately requiring shutdown and re-modification, incurring costs far exceeding the initial budget.

Such issues highlight the importance of qualified personnel following standardized procedures. Additionally, the following misconceptions should be avoided:

-

Over-Reliance on Universal Fittings: Gaskets, bolts, and other accessories must comply with explosion-proof and oil-resistant standards.

-

Ignoring Fluid Compatibility: If the fuel contains a high proportion of biodiesel (e.g., B20), confirm that the LC Meter materials (e.g., cast aluminum, stainless steel) are corrosion-resistant.

Conclusion

Installing an LC Positive Displacement Flow Meter typically requires targeted modification of existing fuel pipelines to ensure measurement accuracy, system safety, and long-term stability. This modification centers on in-line installation, achieved through flanged or threaded connections. Users are advised to engage professional teams for preliminary assessment and implementation and select original accessories compliant with international standards. Only by comprehensively considering fluid characteristics, pipeline conditions, and operational requirements can the technical advantages of PD flow meters be fully leveraged, providing reliable data support for fuel management.