Prevent DEF Mis-Filling: Save on Diesel Tank Repair

The True Cost of DEF Mis-Filling: Protecting Your Diesel Tanks and Your Bottom Line

In today's world of advanced diesel engines, Diesel Exhaust Fluid (DEF) is essential for meeting strict emissions standards. But its very presence introduces a significant, often costly, risk: accidentally putting DEF in a diesel tank. This seemingly small error can lead to massive DEF in diesel tank repair costs, crippling operations and incurring hefty expenses. If you're a fuel equipment supplier, a lubricant or fluid handling provider, or an automotive aftermarket specialist, understanding and promoting solutions to this problem is crucial for your business and your customers.

This article dives deep into the severe consequences of DEF mis-filling, the associated repair expenses, and, most importantly, unveils an ingenious yet simple solution: the DEF Mis-Filling Prevention Device (MFPD), a magnetic adapter designed to work seamlessly with a compatible DEF pump nozzle. This technology ensures DEF only goes where it belongs, saving money, time, and headaches.

I. The Alarming Impact: Understanding DEF in Diesel Tank Repair Cost

Accidentally mixing DEF with diesel fuel is far more common and damaging than many realize. DEF is an aqueous urea solution; when it comes into contact with diesel, it doesn't mix. Instead, it can crystallize and separate, leading to a cascade of expensive problems:

-

Fuel System Contamination: DEF crystals can quickly clog fuel lines, filters, and even delicate fuel injectors. The entire fuel delivery system, from the tank to the engine, becomes compromised.

-

Engine Damage: If DEF reaches the combustion chamber, the consequences can be catastrophic. The urea crystals can abrade internal engine components, foul injectors, and lead to severe, irreparable engine damage.

-

SCR System Malfunction (Indirect): Running a vehicle on DEF-contaminated diesel prevents the Selective Catalytic Reduction (SCR) system from functioning correctly. This triggers emission system faults, often forcing the vehicle into a "limp mode," severely limiting its power and speed.

-

Extensive Repair Expenses: The financial burden of DEF contamination is far from trivial. Repairs typically involve:

-

Thorough draining and flushing of the entire diesel fuel tank.

-

Replacement of all fuel filters and often the fuel lines.

-

Intensive cleaning or outright replacement of fuel injectors.

-

Inspection and potential replacement of the Fuel pump.

-

In the most severe cases, an engine overhaul or complete engine replacement might be necessary, pushing costs into the tens of thousands of dollars.

-

Significant Downtime: Beyond parts and labor, the vehicle's time out of service translates directly into lost productivity and revenue, a critical hit for any fleet or business.

-

Environmental Cleanup: Spills during the repair process can incur additional environmental remediation costs and fines.

-

Given these potential costs, preventing DEF mis-filling isn't just a good idea; it's a financial imperative for any business relying on diesel-powered equipment.

II. The Smart Safeguard: Preventing Mis-Filling with Magnetic Technology

The most effective strategy to eliminate the daunting DEF in diesel tank repair cost is to prevent mis-filling before it ever happens. This is where an ingenious, yet remarkably simple, technological solution shines: the DEF Mis-Filling Prevention Device (MFPD).

This system operates on a fundamental physical interlock:

-

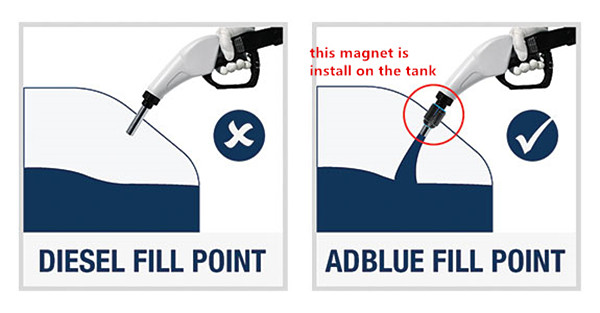

The DEF Magnetic Adapter (MFPD): This small, specialized adapter, often referred to by its abbreviation MFPD, is designed for installation inside the vehicle's DEF fill pipe. It contains a precisely engineered magnetic component.

-

The Compatible DEF Pump Nozzle: The DEF pump nozzle itself is specifically designed with an integral magnetic interlock-actuated mechanism.

How it works seamlessly:

When a DEF pump nozzle is inserted into a fill pipe that lacks the corresponding DEF Magnetic Adapter (MFPD), the nozzle's internal mechanism remains locked. This crucial design feature means the nozzle won't allow DEF to flow. No liquid can enter an incompatible tank, guaranteeing safety and preventing costly errors.

Conversely, when the DEF pump nozzle is inserted into a fill pipe equipped with the MFPD, the magnetic adapter in the fill pipe interacts with the nozzle's magnetic interlock. This magnetic connection "unlocks" the nozzle, permitting DEF to flow freely and safely into the correct tank.

This robust, two-part system creates an almost impenetrable barrier against mis-filling, ensuring that DEF is dispensed exclusively into its designated tank.

III. The Unseen Benefits: Beyond Preventing Repair Costs

Adopting this magnetic mis-filling prevention technology offers advantages that extend far beyond simply avoiding DEF in diesel tank repair costs:

-

Guaranteed Safety: The primary, undeniable benefit is the elimination of dangerous and financially crippling fuel system contamination. By physically preventing mis-filling, you remove the risk of severe engine damage and the associated financial devastation.

-

Significant Cost Savings:

-

Direct Repair Avoidance: No mis-filling means no need for expensive fuel system flushing, part replacements, or engine overhauls. This is where substantial money is saved directly.

-

Reduced Downtime: Vehicles remain operational, preventing the costly loss of productivity and revenue that comes with sidelined equipment.

-

Minimized Waste: Eliminates the need to dispose of contaminated fuel and DEF, which can be an expensive and environmentally sensitive process.

-

-

Enhanced Operational Efficiency: The system streamlines the refueling process by removing the constant worry of mis-filling. Operators can confidently dispense DEF without tedious manual checks or the fear of making a costly mistake.

-

Complete Peace of Mind: For fleet managers, vehicle owners, and equipment operators, the assurance that accidental mis-filling is virtually impossible brings invaluable peace of mind, allowing them to focus on core operations.

-

Assured Regulatory Compliance: Prevents scenarios where vehicles might be forced into "limp mode" due to DEF contamination, ensuring continuous adherence to stringent emission standards and avoiding potential fines.

-

Environmental Protection: Proactively avoids the potential for hazardous spills of contaminated liquids, contributing directly to environmental safety and corporate responsibility.

IV. Your Value Proposition: Targeting Diverse Audiences

This innovative mis-filling prevention technology offers a compelling value proposition across your diverse customer segments:

-

For Fuel Equipment Suppliers and Distributors: You're on the front lines, providing fueling solutions. By integrating the MFPD and compatible DEF pump nozzles into your product lines, or by offering them as essential upgrades, you solidify your position as a leader in safety and innovation. You can provide complete, worry-free DEF dispensing solutions that directly address a major pain point for your customers. This significantly enhances your product portfolio, making your Fuel pumps, dispensers (surtidores), and storage tank offerings more attractive and competitive in the market.

-

For Lubrication Equipment and Solution Providers: While your primary focus might be on lubricants, a significant portion of your customer base operates diesel fleets and machinery that also consume DEF. By strategically expanding your offerings to include DEF transfer and safety solutions, particularly those featuring the MFPD and compatible DEF pump nozzle, you provide immense added value. This helps your customers manage all their critical fluids safely and efficiently, strengthening your reputation as a comprehensive fluid handling partner.

-

For Industrial and Automotive Aftermarket Suppliers: Your customers are constantly searching for reliable parts and practical solutions for maintenance and repair. The MFPD and DEF pump nozzle are perfect additions to your inventory of dispenser accessories and hoses. By offering these specialized components, you empower your clients to proactively prevent incredibly costly repairs, significantly improve their operational reliability, and enhance the service they provide to their own end-users. This directly caters to their fundamental need for practical, effective, and cost-saving solutions in industrial maintenance and automotive servicing.

-

For Companies with Specific Fluid Handling Needs (e.g., Agricultural, Mining, Chemical Transport):

-

Agricultural Fuel or Chemical Transport: Modern farm machinery increasingly relies on DEF. Accidental mis-filling on a farm can ruin expensive equipment and cause severe operational delays during critical planting or harvesting seasons. Implementing MFPDs on farm DEF tanks and utilizing compatible DEF pump nozzles provides vital protection, ensuring continuous operation and preventing expensive repairs to specialized agricultural equipment.

-

Mining Fuel Transport and Integrated Industrial Suppliers: Mining sites are challenging environments where equipment downtime is exorbitantly costly. Preventing DEF in diesel tank repair cost for heavy mining vehicles is absolutely paramount. Integrating the MFPD directly into mining vehicle DEF fill pipes and supplying robust DEF pump nozzles ensures that these vital machines remain operational, safeguarding productivity and profitability in the most demanding conditions.

-

V. Simple Implementation, Massive Savings

Implementing the DEF Mis-Filling Prevention Device is straightforward:

-

Vehicle Integration: The MFPD is typically a simple, durable adapter that is secured inside the vehicle's DEF fill pipe. This is a quick, one-time installation that provides permanent, foolproof protection.

-

Dispensing Equipment Compatibility: It's essential to ensure that the DEF pump nozzle used at the dispensing station (whether a dedicated DEF dispenser or a mobile DEF transfer unit) is the compatible, magnetic interlock-actuated type.

This dual-component system creates an almost impenetrable barrier against mis-filling. If an incompatible nozzle (e.g., a standard diesel nozzle) is inserted, or if the correct DEF nozzle is inserted into a tank not equipped with the MFPD, no flow will occur. This guarantees safety and virtually eliminates the potential for costly errors.

Conclusion: Invest in Prevention, Protect Your Profits

The threat of high DEF in diesel tank repair costs is a very real and significant concern for any business operating modern diesel vehicles. However, with the innovative DEF Mis-Filling Prevention Device (MFPD) and its complementary DEF pump nozzle, this substantial risk can be effectively eliminated.

For fuel equipment suppliers, lubricant solution providers, industrial and automotive aftermarket partners, and specialized fluid handling companies, offering this advanced technology isn't just about selling a product. It's about providing a critical safety and cost-saving solution that directly addresses a major industry vulnerability. By educating your customers on the tangible benefits of these devices, you empower them to protect their valuable assets, ensure regulatory compliance, and significantly streamline their operations.

Don't let costly mis-filling mistakes jeopardize your business. Invest in smart prevention today and safeguard your tomorrow.