Guide to Flow Meter Calibration & Selection: Why It’s Your Key to Profit and Performance

Ultimate Guide to Flow meter Calibration & Selection: Why It’s Your Key to Profit and Performance

The Unseen Hero of Your Operations

In the high-stakes world of logistics, construction, mining, and fuel distribution, every drop counts. For a truck driver, it’s about maximizing mileage and controlling costs. For a gas station owner, it’s about honest dispensing and a healthy bottom line. For an industrial fleet manager, it’s about accurate inventory and preventing theft. At the heart of all these operations is one unassuming but critical device: the Flow meter.

Often overlooked until there's a problem, a properly functioning flow meter is the key to financial accuracy and operational efficiency. When it's not working correctly, the financial losses can be staggering, leading to inaccurate billing, costly fuel discrepancies, and even regulatory fines. This guide will take you deep into the world of flow meter technology, covering why calibration is not just an option but a necessity, how to perform it correctly, and how to select the perfect meter for your specific needs, from 12V diesel pumps to large-scale industrial systems.

Why Calibration Is Not a Choice, But a Necessity

Think of your flow meter like a finely tuned instrument. Over time, due to mechanical wear, changes in fluid viscosity, or just the natural aging of components, its accuracy can drift. This phenomenon, known as accuracy drift, can have serious consequences.

The High Cost of Inaccuracy

A small error in a flow meter's reading can lead to significant financial losses. For a gas station or fuel dispenser, a 1% under-delivery means you’re losing money on every single gallon sold. Conversely, a 1% over-delivery to a customer could lead to disputes and damage to your reputation. A fleet manager dealing with a trucking operation can see thousands of dollars in unaccounted-for fuel costs annually due to a single inaccurate fuel flow meter on a diesel pump. In mining and construction, where millions are spent on fuel, even a slight inaccuracy can lead to massive discrepancies in cost accounting and budget overruns. Calibration is the only way to ensure every drop is accounted for, allowing you to accurately track consumption and budget with confidence.

Meeting Regulatory and Industry Standards

For many businesses, especially those in the gas station and oil distribution industries, accurate measurement is a legal requirement. Regulatory bodies and government agencies have strict standards to protect consumers and ensure fair trade. For example, standards like OIML R117 or API MPMS dictate the acceptable margin of error for fuel dispensers. Regular calibration and the issuance of calibration certificates are often required for passing audits and maintaining compliance. Ignoring these standards can result in hefty fines, business closures, and a loss of public trust.

Maximizing Efficiency and Preventing Waste

Beyond the financial and legal aspects, accurate flow meter readings are crucial for maximizing operational efficiency. In oil depots and large industrial settings, a calibrated flow meter is your most reliable tool for inventory management. It helps prevent "run, leak, drip, and escape"—a term for unaccounted for fuel. In agriculture, it ensures you're applying the correct amount of fertilizer or pesticide, preventing waste and ensuring crop health. For oil tankers, a precise flow meter on a 12V diesel pump with meter ensures you’re delivering the exact amount of fuel requested, eliminating disputes and reinforcing your professional reputation.

The Step-by-Step Flow Meter Calibration Process

Calibrating a flow meter doesn’t have to be a daunting task. By following a systematic approach, you can ensure your equipment is performing at its best.

1. The Essentials Before You Begin

Before you start, gather all the necessary tools. You'll need a calibration console, a certified reference meter, and a clean fluid sample. For a 12V diesel pump with meter, ensure the power supply is stable to avoid any electrical interference that could skew your results. Safety is paramount; make sure all connections are secure and the area is well-ventilated, especially when working with flammable liquids like diesel.

2. Static Calibration (Bench Testing)

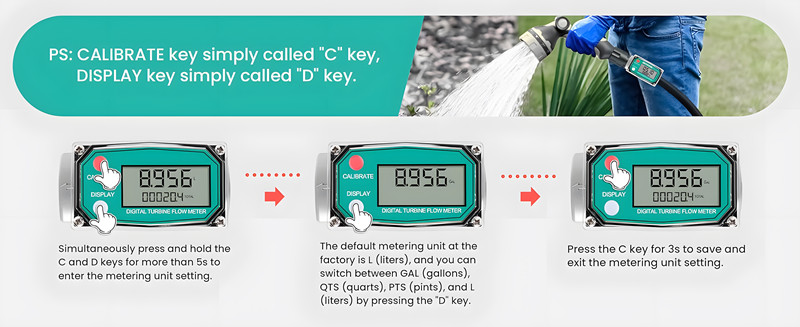

This is the initial phase of calibration where you compare the flow meter's readings against a certified reference standard. By running the fluid through both the meter being tested and the reference meter, you can accurately measure any discrepancies. The key adjustment here is the K-factor, which represents the number of pulses a meter outputs per unit of volume (e.g., pulses per liter or gallon). If your meter is reading higher or lower than the reference, you simply adjust the K-factor until the readings align.

3. Dynamic Calibration (Field Testing)

While bench testing is crucial, it’s equally important to test the flow meter under real-world operating conditions. This involves running fluid at the actual pressure, temperature, and flow rate you would normally experience. This step helps identify issues that might not be apparent during static testing, such as errors caused by fluid pulsation or changes in viscosity at different temperatures. For diesel pump systems, this dynamic test is essential to ensure accuracy during actual dispensing.

4. Validation & Documentation

The final step is to record your findings and validate the results. Document the pre-calibration readings, the adjustments made, and the final post-calibration readings. Most industries have an acceptable error tolerance (e.g., ±1% for general industrial use, but a much tighter ±0.5% for fuel dispensing). Once validated, you should issue a calibration certificate for the device. This document is a crucial record for audits, compliance checks, and demonstrating your commitment to accuracy and quality.

How to Select the Right Flow Meter for Your Industry

Choosing the correct flow meter for your application is as critical as calibrating it. The wrong meter can lead to continuous headaches, inaccurate readings, and premature failure.

1. Fluid Compatibility Is King

The first and most important consideration is the type of fluid you'll be measuring. For diesel and gasoline, you must use a meter designed for non-conductive liquids, such as a turbine meter, gear meter, or Coriolis meter. Trying to use an electromagnetic flow meter, which requires a conductive fluid, for diesel will simply not work. For abrasive slurries common in mining operations, a diaphragm or paddle wheel meter might be more suitable due to their durability and resistance to clogging.

2. Power & Signal Output

Your meter must be compatible with your system's power source. For a small 12V diesel pump with meter or a portable fuel skid, you'll need a meter that operates on 12V/24V DC. Additionally, consider the type of output signal you need. A pulse output is perfect for simple fuel counters, while a 4-20mA output is ideal for integrating with complex industrial control systems. For remote monitoring, an RS485/Modbus output allows you to track fuel usage from a central location.

3. Environmental Resilience

The environment in which your meter operates will dictate its required features. If you are a gas station or a company handling flammable liquids, an explosion-proof certification (ATEX/IECEx) is mandatory to ensure safety. For mining and agriculture, where equipment is exposed to dust, moisture, and debris, a meter with a high IP rating (e.g., IP67) is essential to prevent internal damage and maintain reliability.

Frequently Asked Questions (FAQ)

Q1: Why is my flow meter showing incorrect readings?

This is a common issue with several possible causes. It could be due to a dirty sensor, air bubbles in the liquid, or electrical interference. Regularly cleaning the sensor and installing air eliminators can help.

Q2: How often should I calibrate my flow meter?

A general rule of thumb is annually. However, for high-usage systems like those in gas stations or large mining fleets, it's recommended to calibrate every six months to ensure peak accuracy and compliance.

Q3: Can I use an electromagnetic flow meter for diesel?

No, you cannot. Diesel is a non-conductive liquid. An electromagnetic flow meter requires the fluid to be conductive to generate a magnetic field and produce a reading. For diesel, you must use a mechanical or mass-based meter.

Q4: What certifications are required for fuel dispensers?

Internationally, OIML R117 and API MPMS are the key standards. In the U.S., look for NTEP certification, and in Europe, MID 2014/32/EU is the standard.

Q5: How do I maintain a flow meter in dusty conditions (e.g., agriculture)?

Regular maintenance is key. Use meters with IP65+ rated enclosures, install inline filters to prevent debris from damaging internal components, and regularly inspect mechanical parts for wear and tear.

Conclusion: Your Partner in Precision

Whether you are a gas station owner prioritizing customer trust, a trucking company controlling your fleet's fuel flow meter costs, or a mining operation demanding durability, the right flow meter and a commitment to calibration are non-negotiable.

Choosing a certified, high-quality meter that matches your application and consistently maintaining it will not only prevent costly errors but also ensure your operations run smoothly and profitably.

Need a customized solution? Don’t leave your business's accuracy to chance. Contact us for expert advice on flow meter selection, professional calibration services, or OEM supply tailored to your industry's unique needs.