Description

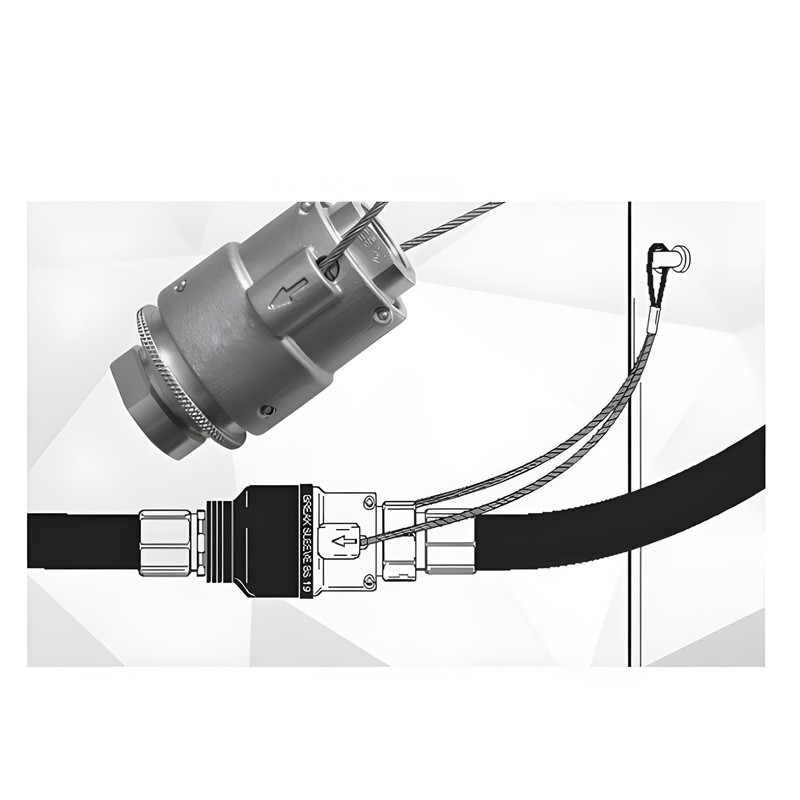

LPG Separator Dispenser Parts breakaway

LPG Series Breakaway Couplings: Enhanced Safety and Efficiency in LPG Transfer Operations

The LPG Series Breakaway Couplings are engineered to ensure safety and operational reliability during liquefied petroleum gas (LPG) transfer processes. Designed to prevent accidents caused by unintended vehicle movement, these couplings automatically disconnect when excessive tension is applied (e.g., if a vehicle drives away while the nozzle remains connected). Upon separation, dual internal back-pressure poppet valves close instantly, eliminating gas leakage and minimizing environmental risks.

Key Features:

Material and Durability

The male nipples undergo heat treatment to enhance hardness and resistance to mechanical stress.

Stainless steel poppet valves ensure corrosion resistance and longevity, even under extreme temperatures (-30°C to +110°C).

Nitrile O-rings (NBR) provide reliable sealing against LPG gas permeation.

Design Flexibility

Available in push-type, push-pull-type, and nitrile rubber-covered sleeve configurations to suit diverse operational requirements.

Thread size standardized at 3/4" NPT for compatibility with common LPG infrastructure.

Safety Mechanism

The coupling disconnects via sleeve retraction, triggering valve closure on both ends to prevent hazardous gas release.

Strict prohibition of connection/disconnection under pressure ensures user safety.

Applications

Primarily used in LPG fuelling stations, loading/unloading terminals, and industrial transfer systems.

DM Series Breakaway Couplings: Corrosion-Resistant Safety for

Critical Applications

The DM Series Breakaway Couplings combine robust design with corrosion-resistant materials to mitigate pull-away accidents in demanding environments. Engineered to break at a predetermined load, these couplings safeguard equipment and infrastructure while minimizing downtime and environmental impact.

Key Advantages:

Material Superiority

Constructed from stainless steel, ensuring resistance to chemical corrosion and prolonged service life.

Impermeable materials specifically validated for LPG compatibility.

Precision Engineering

A diverted breaking point ensures predictable separation at a set load, reducing equipment damage.

Automatic dual-side valve closure upon disconnection prevents product loss and hazardous leaks.

Operational Efficiency

Sleeve retraction mechanism simplifies disconnection, aligning with industry safety protocols.

Compatible with standard LPG transfer systems, requiring no pressure during connection/disconnection.

Environmental and Economic Benefits

Reduces cleanup costs and regulatory penalties by preventing gas release.

Low maintenance requirements due to durable construction, ideal for high-frequency use in fuelling stations and industrial plants.