Description

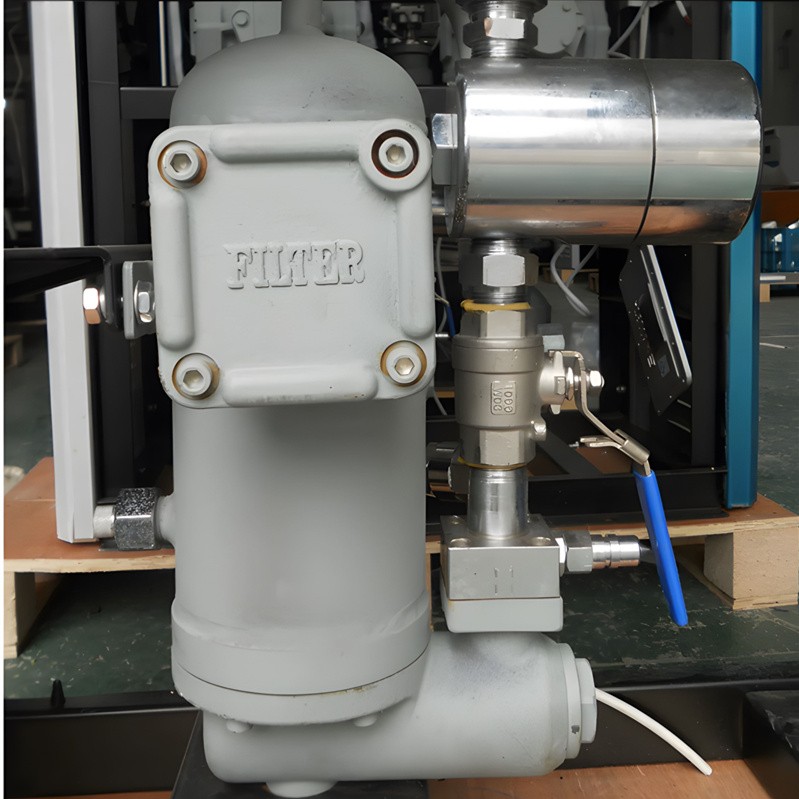

LPG Dispenser with Parts Check Valve Filter Differential Valve Solenoid Valve Nozzle Cover Pressure Gauge

Liquefied Petroleum Gas (LPG) Separator: Function, Advantages, and Specifications

I. Function of the LPG Separator

The LPG separator is a critical device in petroleum gas processing, designed to separate liquid hydrocarbons (e.g., ethane, propane, butane) from natural gas. This separation ensures the production of high-purity natural gas by removing liquid components that could interfere with downstream processing, transportation, or combustion. Key applications include:

Oil fields: Pre-treatment of raw natural gas.

Gas processing plants: Enhancing gas quality for industrial use.

Storage facilities: Preventing liquid accumulation in pipelines or tanks.

The separation process typically relies on pressure reduction, cooling, and gravity/centrifugal forces to condense and isolate liquid fractions.

II. Advantages of the LPG Separator

Enhanced Gas Purification Efficiency

By removing liquid contaminants, the separator ensures natural gas meets purity standards for pipelines, power plants, or residential use.

Reduces fouling in compressors and turbines, improving operational reliability.

Minimized Gas Losses

Volatile liquid components (e.g., propane) are recovered instead of being lost to evaporation.

Cost savings through efficient resource utilization and compliance with environmental regulations.

Extended Equipment Lifespan

Liquid hydrocarbons can corrode pipelines and valves due to water or acidic impurities.

The separator mitigates corrosion, reducing maintenance costs and downtime.

Improved Safety

High-purity LPG burns more efficiently and safely, minimizing explosion risks.

Separation ensures compliance with safety standards (e.g., ISO 13686) for handling flammable gases.

III. Technical Specifications

Parameter Value

Name LPG Separator

Maximum Pressure 25 bar

Delivery Pressure 40 bar

Filter Precision 0.08 mm

Dimensions 44 × 31 × 32 cm

Weight 26 kg

IV. Expanded Applications

Industrial Use: Integration into gas-fired power plants or chemical manufacturing.

Environmental Benefits: Reduces methane emissions by capturing volatile organic compounds (VOCs).

Scalability: Modular designs allow adaptation to small-scale (e.g., rural gas stations) or large-scale (e.g., offshore platforms) operations.

V. Conclusion

The LPG separator is indispensable in modern gas processing, balancing efficiency, safety, and sustainability. Its role in resource optimization and environmental protection underscores its value across energy sectors.