How to Use 12 Volt Pumps Correctly in the US?

How to Use 12 Volt Pumps Correctly in the US: A Guide to Safety and Core Skills

Meta Description: Discover the many uses of a pump 12v dc. This guide explains the differences between a 12v oil transfer pump, a 12 volt def pump, and why you must be cautious with a diesel Fuel pump 120 volt. Learn to transfer fluids safely and efficiently.

12V DC Pumps: The Ultimate Solution for Mobile & Emergency Power

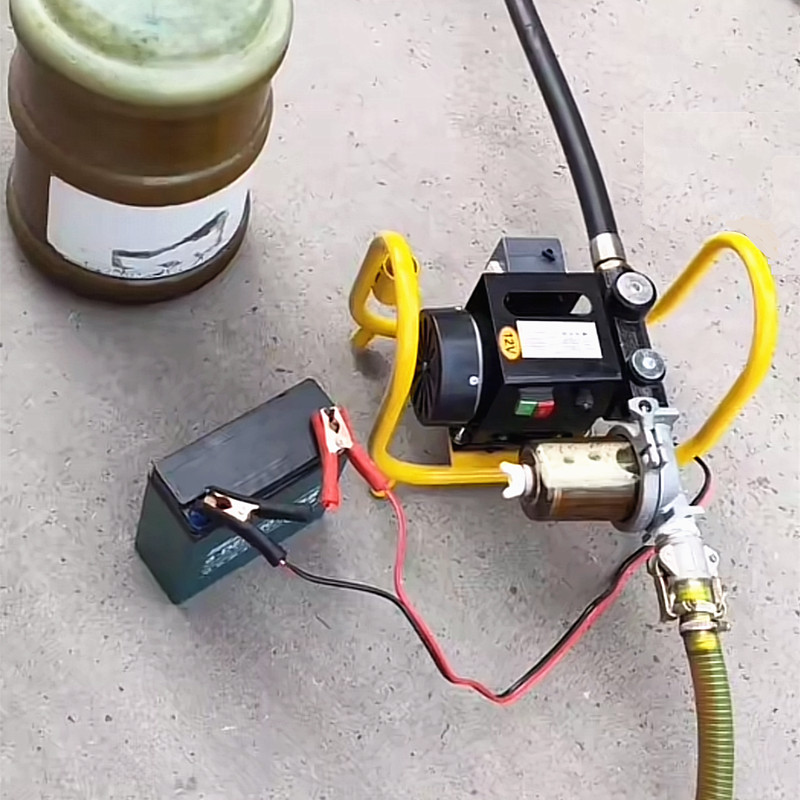

In a world that’s always on the move, having the right tools for the job is essential. Whether you're on a farm, at a remote job site, in your garage, or facing an emergency, you don't always have access to a standard wall outlet. This is where 12V DC pumps shine. These incredibly versatile tools are designed to run directly from the electrical system of a car, truck, boat, or RV. By simply connecting to a vehicle's battery or plugging into a cigarette lighter socket, you can move fluids without needing household alternating current (120V AC).

The core concept is simple: these pumps are built to run on the low-voltage, direct current (DC) power that vehicles provide. Understanding the match between the pump's requirements and your vehicle's power supply, specifically the voltage (12V DC) and the current draw (Amperage), is the key to using them effectively.

Core Advantages of 12V Pumps:

-

Portability: Their greatest strength is the ability to be used anywhere. You are no longer tied to a power outlet, giving you the freedom to work in the field, on the water, or during a power outage.

-

Safety: Generally, 12-volt systems are safer to work with than high-voltage 120V AC systems, especially when you are around liquids. The risk of serious electrical shock is significantly lower.

-

Compatibility: The 12V DC standard is universal across almost all consumer and commercial vehicles, from sedans and pickups to tractors and boats. This makes them a widely compatible and practical solution for countless users.

The Three Common Pumps: Stop Using the Wrong Tool for the Job!

While they might look similar, not all pumps are created equal. The single most important difference between them is the type of fluid they are designed to handle. Using the wrong pump for the liquid you need to move can lead to pump failure, costly damage to your equipment, and even dangerous situations. Let’s break down three common types of pumps you'll encounter and clarify when to use each one.

1. The 12V Oil Transfer Pump

Keywords: lube pump, diesel transfer pump, fuel transfer, viscous liquids

Design and Purpose: As the name suggests, a 12v oil transfer pump is engineered specifically to handle the challenges of moving oils and other medium-to-high viscosity liquids. Their internal gears and motors are built to push thicker fluids that would clog or burn out a weaker pump.

Common Applications:

-

Pumping engine oil, transmission fluid, or hydraulic oil out of barrels and into machinery.

-

Transferring diesel or biodiesel fuel from a storage container into a vehicle or equipment fuel tank.

-

Draining used or waste oil from engines for easy disposal and recycling.

Material Features:

-

Durable Body: The pump housing is typically made from robust metals like cast iron or aluminum, or from heavy-duty, oil-resistant engineered plastics that won't degrade over time.

-

Resistant Seals: The internal seals, gaskets, and hoses are made from materials that can withstand the chemical compounds found in petroleum products, preventing leaks and corrosion.

Pro Tips & Precautions:

-

Check Compatibility: Always double-check that the pump's materials are compatible with the specific type of oil you are transferring. Some synthetic oils or additives can be harsh on certain plastics or seals.

-

Temperature Matters: Viscous fluids like gear oil get much thicker in cold weather, which will slow down the pump's flow rate. For best results, try to work in warmer temperatures or allow the oil to warm up to room temperature first.

-

Clean After Use: Don't let old oil sit in the pump. After you're done, run a small amount of flushing oil or diesel through it to clean the internals. This prevents oil from solidifying and causing blockages later on.

2. The 12 Volt DEF Pump

Keywords: AdBlue transfer pump, urea pump, Selective Catalytic Reduction (SCR) system

Design and Purpose: A 12 volt DEF pump has one highly specialized job: to transfer Diesel Exhaust Fluid (DEF). DEF, also known as AdBlue in many parts of the world, is a urea-based solution that is crucial for the emissions systems of modern diesel engines.

Core Application:

-

Refilling the DEF tank on large diesel trucks, pickups, agricultural machinery, or any vehicle equipped with an SCR (Selective Catalytic Reduction) system.

Material Features:

-

Extreme Compatibility: This is the most critical feature. DEF is highly corrosive to many materials, including copper, zinc, aluminum, and regular steel. A dedicated DEF pump must have all its wetted parts—the pump body, seals, and hoses—made from stainless steel or special-grade polypropylene (PP).

-

Contamination Prevention: Using a pump made of the wrong material will cause a chemical reaction with the DEF. This not only destroys the pump but also contaminates the fluid with metal ions. If this contaminated DEF enters your vehicle's SCR system, it can crystallize and cause catastrophic damage, leading to thousands of dollars in repairs.

Pro Tips & Precautions:

-

DEF-Only Rule: Never, under any circumstances, use a pump that is not explicitly labeled as "DEF-Compatible" to transfer DEF.

-

Keep It Clean: The SCR system is incredibly sensitive. Ensure your pump, hoses, and containers are perfectly clean to prevent dirt, debris, or any other fluid from contaminating the DEF.

-

Watch the Temperature: DEF can freeze at around 12°F (-11°C). If you live in a cold climate, choose a pump designed for cold weather use or make sure you store your DEF and conduct transfers in a heated area.

3. The Diesel Fuel pump 120 Volt - A Common Misconception

Keywords: AC powered pump, fixed installation, high-flow pump

Design and Purpose: Here is where a lot of confusion can happen. A diesel fuel pump 120 volt is a completely different tool. This is an alternating current (AC) pump, meaning it must be plugged into a standard 120-volt wall outlet, the same kind you use for household appliances. These pumps are designed for high-flow, stationary applications where speed is a priority. You'll often find them mounted on large, fixed fuel tanks on farms, at construction sites, or in industrial settings.

Key Differences and Risks:

-

Power Source: The most critical difference is the power source. It runs on 120V AC, not 12V DC. Plugging a 120V pump into a 12V car battery will do nothing, and attempting to connect a 12V pump to a 120V outlet will instantly destroy it and create a serious electrical hazard.

-

Lack of Portability: Because it relies on a wall outlet, its use is restricted to locations with access to the power grid. It is not a mobile solution.

-

Higher Voltage Safety: Operating high-voltage equipment around a flammable liquid like diesel requires a heightened level of safety awareness and proper grounding to prevent sparks.

Which One Should You Choose?

-

If you need to refuel equipment from your vehicle in a field, at a campsite, or anywhere away from a building, you need a 12V diesel transfer pump (which is a type of 12v oil transfer pump).

-

If you have a large, stationary fuel tank next to a barn or shop and need to fill large vehicles quickly, and you have a standard power outlet nearby, the 120V diesel pump is the correct choice.

Universal Safety Guide & FAQ for Using 12V Pumps

Safety First: Core Operating Rules

No matter which 12V pump you use, following these safety rules is non-negotiable.

-

Connect Power Correctly: Always connect the pump's positive (red, +) clamp to the positive terminal of the battery first. Then, connect the negative (black, -) clamp to the negative terminal or a solid metal ground point on the vehicle's frame. When disconnecting, reverse the order: black first, then red. This minimizes the chance of sparks.

-

Check the Fuse: Ensure the pump's power cord has an inline fuse with the correct amperage rating. This is your number one defense against an electrical short that could cause a fire. If the pump blows a fuse, don't just replace it—find out why it blew.

-

Ventilation! Ventilation! Ventilation! If you are transferring flammable liquids like diesel or gasoline, you must do it in a well-ventilated area. Vapors can build up in enclosed spaces and create an explosion risk. Keep the area clear of any open flames, sparks, or ignition sources.

-

Wear Protective Gear: Always wear safety glasses to protect your eyes from splashes and chemical-resistant gloves to protect your hands.

Frequently Asked Questions (FAQ)

Q: My pump is running, but it's not moving any liquid. What's wrong? A: This is a common issue. First, check that your intake hose is fully submerged in the fluid and that all connections are airtight—a small air leak will prevent the pump from creating suction. Second, check if the intake filter or screen is clogged. Finally, for pumps that are not self-priming, you may need to ensure the pump is located below the level of the liquid source to get it started.

Q: The pump's flow rate has become very slow. What should I do? A: A slow flow rate can be caused by a few things. The most common is a low battery; as the battery's voltage drops, the pump motor will slow down. Also, check your hoses for any kinks or sharp bends that could be restricting flow. Finally, as mentioned earlier, cold temperatures will make viscous fluids thicker and harder to pump.

Q: Can I use the same pump for my engine oil and my DEF? A: Absolutely not! This is a critical rule. Cross-contaminating fluids can cause severe damage. Even a tiny residue of oil can ruin an entire tank of DEF and wreck your vehicle's SCR system. The golden rule is: one pump, one type of fluid. Keep your pumps dedicated and clearly labeled.

Q: How do I choose the right 12V pump for my project? A: Follow this simple four-step process:

-

Identify the Fluid: What are you pumping? Oil, diesel, DEF, water? This is the most important question.

-

Determine the Flow Rate: How fast do you need to move the liquid? Flow rates are usually measured in Gallons Per Minute (GPM). A higher GPM is faster but may require more power.

-

Check Your Power Source: Make sure your vehicle's battery and wiring can handle the amperage (Amps) the pump draws. This information is usually on the pump's label.

-

Match the Fittings: Ensure the pump's inlet and outlet ports match the diameter of the hoses you plan to use.

Conclusion: Making the Smart Choice

Correctly using a 12V DC pump can save you an immense amount of time and effort, turning difficult fluid transfer jobs into simple tasks. But the key to success is choosing the right pump for the right job and always putting safety first.

Remember these three final takeaways:

-

Use a 12V Oil Transfer Pump for oils and diesel fuel.

-

Only use a dedicated 12V DEF Pump for Diesel Exhaust Fluid.

-

Pay close attention to voltage. A 120V AC pump is for stationary use with a wall outlet and is not interchangeable with a 12V DC system.

By investing in a high-quality, specialized pump and following proper safety procedures, you will protect your valuable equipment, ensure your own safety, and get the job done right every time.