Detecting Leaks in Gas Station Underground Storage Tank Submersible Pumps

You face serious risks when leaks in underground storage tank submersible pumps go unnoticed. Federal regulations require you to use effective leak detection methods because even a small, undetected leak can contaminate soil and groundwater, leading to cleanup costs that may exceed $500,000. Facilities often discover leaks only during tank decommissioning, which means damage can continue for years. Reliable detecting leaks technology, sourced from a reputable submersible pump supplier, protects your investment and ensures your gas station equipment meets strict safety and environmental standards.

Key Takeaways

-

Use advanced leak detection methods like Automatic Tank Gauges and Continuous Statistical Leak Detection to find leaks early and protect your gas station.

-

Combine multiple leak detection technologies and regular testing to meet federal and state regulations and avoid costly fines or cleanup.

-

Detecting leaks early prevents soil and groundwater contamination, protects the environment, and saves money on repairs and cleanup.

-

Choose reliable submersible pumps with built-in leak detection features, such as Red Jacket or 1.5hp models, for safer and more efficient fuel delivery.

-

Keep detailed records of leak detection tests, maintenance, and training to ensure compliance and support your business during inspections.

Detecting Leaks: Methods

Automatic Tank Gauges

Automatic Tank Gauges (ATGs) represent the industry standard for detecting leaks in underground storage tank submersible pumps. You rely on these systems to monitor fuel and water levels with exceptional precision—down to 1/1000th of an inch. ATGs use magnetostrictive probes that adjust for temperature fluctuations, ensuring accurate inventory tracking and leak detection. These systems continuously record product levels, deliveries, and dispensing activities, allowing you to identify discrepancies that signal leaks.

ATGs trigger alarms when the leak rate exceeds the federal threshold of 0.20 gallons per hour, meeting regulatory requirements for gas station operators. You benefit from automated monitoring, which reduces manual labor and provides early warnings. Modern ATGs also integrate sensors in tank sumps and annular spaces, detecting leaks in both tanks and piping. This technology supports compliance and protects your investment by minimizing environmental risks.

Tip: Pairing ATGs with other leak detection methods enhances reliability and reduces the chance of missing leak events.

Leak Detection Method

Accuracy and Sensitivity

Operational Characteristics and Limitations

Automatic Tank Gauging (ATG)

Detects leaks as small as 0.2 gallons per hour; measures product level and temperature to 1/1000th of an inch.

Provides continuous or frequent automated monitoring; reduces labor; meets regulatory requirements; detects leaks in tank and piping.

Manual Tank Gauging

Less precise; measurements to nearest 1/8 inch.

Labor-intensive; suitable only for small tanks; cannot detect piping leaks.

Continuous In-Tank Leak Detection (CITLD)

Detects leaks at 0.2 gallons per hour with high probability.

Operates continuously; monitors larger tanks; meets federal requirements.

Tank Tightness Testing

Periodic testing only.

Does not detect piping leaks; less effective for early leak detection.

Continuous Statistical Leak Detection

Continuous Statistical Leak Detection (CSLD) technology provides advanced, 24/7 monitoring for underground storage tanks equipped with submersible pumps. You benefit from CSLD’s ability to analyze fuel height and temperature data during idle periods, using statistical algorithms to filter out invalid readings and ensure accurate results. This method operates without interrupting normal tank operations, making it ideal for busy gas stations and construction companies seeking efficient solutions.

CSLD systems, such as those compatible with TLS-450PLUS and TLS4 Automatic Tank Gauges, deliver automatic daily reports and minimize false alarms. You can trust CSLD to meet federal, state, and local regulations for leak detection. The technology supports manifolded tanks, which often include submersible pump systems, ensuring broad applicability for fuel dispenser manufacturers and maintenance providers.

Note: CSLD enhances leak detection by providing continuous data analysis, reducing the risk of undetected leaks and supporting regulatory compliance.

Float and Pressure Sensors

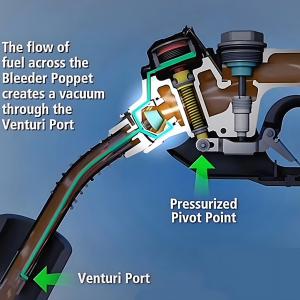

Float and pressure sensors offer reliable, real-time detection of leaks in submersible pump systems. Float sensors monitor liquid levels and trigger alarms when they detect unexpected changes, such as the presence of fuel or water in the annular space of double-wall tanks. For example, the Veeder-Root Model 420 uses a float that rises with liquid presence, activating an alarm to alert you immediately.

Pressure sensors, including line leak detectors, monitor pressure drops in the fuel delivery line between the in-tank turbine pump and the dispenser. Mechanical detectors respond to pressure loss by reducing flow, while electronic detectors disable the pump and trigger alarms. These sensors integrate with monitoring systems to measure electrical resistance or line pressure, providing instant feedback on system integrity.

Testing float and pressure sensors involves simulating leaks or liquid presence to verify functionality. You should include these sensors in your leak detection strategy to ensure comprehensive coverage and rapid response to leak events.

Supplementary Leak Detection Methods

You can strengthen your leak detection program by incorporating supplementary methods alongside electronic sensors:

-

Interstitial monitoring (secondary containment with sensors between tank/piping and environment)

-

Vapor monitoring (detects product vapors in soil)

-

Groundwater monitoring (detects product in groundwater near tanks)

-

Statistical inventory reconciliation (analyzes inventory, delivery, and dispensing data)

-

Manual tank gauging (for tanks up to 2,000 gallons)

-

Line tightness testing (pressure or tracer methods for piping)

These methods provide additional layers of protection, helping you meet regulatory standards and safeguard your facility against environmental contamination. Construction companies and maintenance providers often recommend combining multiple approaches for optimal results.

Callout: Detecting leaks early protects your business, the environment, and your reputation. Use a combination of technologies for best results.

Importance of Leak Detection

Environmental Impact

You protect your business and the community when you prioritize detecting leaks in underground storage tank submersible pumps. Leaks release hazardous chemicals such as benzene, methyl tertiary-butyl ether, and lead into the environment. These substances contaminate soil and groundwater, threatening drinking water sources for millions. Even a small leak, such as ten gallons, can pollute up to twelve million gallons of water. Benzene persists in groundwater for decades, making cleanup difficult and expensive.

-

Leaks from underground fuel systems damage soil, rivers, streams, and air.

-

Petrol contains toxic hydrocarbons, which pose serious health risks.

-

Corrosion in tanks and pipes often causes leaks, especially in older systems.

-

Owners face financial losses from product loss, cleanup costs, and liability for third-party damages.

Leaking underground storage tanks account for about 40% of groundwater contamination in the United States. You risk long-term harm to local ecosystems and costly remediation if leaks go undetected. Construction companies and maintenance providers recommend regular monitoring to prevent these issues.

Alert: Early leak detection safeguards water quality and reduces environmental liability for gas station operators and fuel dispenser manufacturers.

Safety and Compliance

You maintain a safe workplace and meet regulatory standards by detecting leaks promptly. Leaks from submersible pumps release volatile organic compounds (VOCs) that create hazardous conditions. These vapors can lower oxygen levels in confined spaces and reach explosive concentrations. Workers and nearby residents face risks from ingestion, inhalation, and direct contact with contaminated soil or water.

-

Leaks may cause bodily injury, property damage, and natural resource claims.

-

Tank age, construction, and monitoring effectiveness influence risk.

-

Common leak sources include submersible pumps, spill buckets, piping, and sumps.

-

Corrosion and installation issues contribute to costly releases.

Excavation and trenching during cleanup present collapse hazards. You must follow OSHA HAZWOPER training and strict safety protocols to protect workers. Regulatory agencies require you to use certified leak detection systems and maintain thorough records. Gas station equipment maintenance companies and construction firms rely on advanced technologies to ensure compliance and minimize risk.

Tip: Detecting leaks early helps you avoid fines, legal claims, and business interruptions. Reliable leak detection supports your reputation and operational continuity.

Technologies in Submersible Pumps

Submersible Turbine Pumps

You rely on submersible turbine pumps (STPs) to deliver fuel efficiently from underground storage tanks to dispensers. These pumps operate as submerged motor and pump assemblies, creating the pressure needed to move fuel through riser pipes and overcome friction losses. STPs maintain positive pressure, which prevents vapor lock and cavitation, ensuring consistent fuel flow for your customers. The submerged design also reduces vapor emissions and maximizes fuel withdrawal from the tank bottom. Proper installation, including secure sealing and explosion-proof wiring, is essential for safe operation in hazardous environments. Gas station construction companies and equipment maintenance providers often recommend STPs for their reliability and safety features.

Tip: STPs offer fewer leak points than older suction pumps, enhancing leak prevention and supporting regulatory compliance.

Red Jacket Submersible Pump

Red Jacket submersible pumps set the industry standard for leak detection and fuel dispensing performance. You benefit from integrated Red Jacket FXV Mechanical Line Leak Detectors (MLLDs), which perform automatic leak tests at rates up to 3 gallons per hour. These detectors restrict fuel flow when leaks are detected, ensuring compliance with EPA regulations. Red Jacket pumps feature advanced packer manifold designs, automatic fuel drains, and electrical disconnects for safety. The robust construction withstands extreme temperatures and corrosive environments, including ethanol and methanol blends. Maintenance is straightforward, requiring no special tools, and the pumps are compatible with various pipeline types. Fuel dispenser manufacturers and maintenance companies value Red Jacket’s reliability, UL listing, and third-party certifications.

-

MLLDs provide hourly leak monitoring for cost-effective compliance.

-

Stainless steel components resist corrosion, proven in rigorous testing.

-

Flexible installation suits fiberglass, steel, and double-wall piping.

Note: Red Jacket pumps deliver fast, reliable leak detection, making them a preferred choice for gas station equipment maintenance.

1.5hp Submersible Pump

You find 1.5hp submersible pumps widely used in UST systems for their efficiency and adaptability. These pumps feature high-efficiency motors, adjustable lengths, and advanced corrosion protection. The technical specifications include:

|

Specification |

Details |

|---|---|

|

Power |

1.5 HP / 1.1 kW |

|

Rated Voltage |

220 V, 50 Hz |

|

Pump Body Material |

Cast Iron with Epoxy Coating |

|

Base Material |

Stainless Steel AISI 304 |

|

Impeller Type |

Stainless Steel VORTEX |

|

Port Size |

2" |

|

Flow Rate |

Up to 650 l/min (39 m³/h) |

|

Head |

Up to 15 m |

These pumps integrate mechanical or electronic leak detection systems, providing automatic shutdown at 3 gallons per hour and precision detection options for monthly and annual compliance. You benefit from features like AUTO-LEARN® startup, active air eliminators, and contractor electrical disconnects for safe maintenance. The design supports biofuel blends and offers long-term reliability, making it ideal for fuel dispenser manufacturers and equipment maintenance companies.

Callout: Choosing the right submersible pump and integrating advanced leak detection technology ensures safe, efficient, and compliant fuel dispensing operations.

Regulatory Requirements

Federal and State Standards

You must follow strict federal regulations when detecting leaks in underground storage tank submersible pumps. The Environmental Protection Agency (EPA) sets requirements in 40 CFR Part 280, which include:

-

Install liquid-tight under-dispenser containment (UDC) for new dispenser systems after April 11, 2016.

-

Monitor piping and dispenser systems for releases every 30 days using approved methods such as automatic line leak detectors or interstitial monitoring.

-

Test release detection equipment annually to confirm proper operation.

-

Use secondary containment and interstitial monitoring for piping installed or replaced after April 11, 2016.

-

Conduct monthly walkthroughs and annual checks of containment sumps and release detection equipment.

State-level standards often exceed federal requirements. Many states adopt National Fire Protection Association (NFPA) fire codes and set additional rules based on local conditions. You may encounter stricter enforcement or unique protocols depending on your location. State agencies design their underground storage tank programs to address specific environmental risks and prioritize community safety.

Note: You should consult both federal and state regulations to ensure your facility remains compliant and avoids costly penalties.

Testing and Maintenance

You need to test electronic and mechanical components of release detection systems at least once every year. This includes automatic tank gauges, probes, sensors, line leak detectors, vacuum pumps, pressure gauges, and handheld sampling equipment. Follow manufacturer instructions, recognized codes of practice, or agency requirements for each test. Annual operational tests must verify alarms, system configuration, battery backup, and communication between sensors and controllers.

|

Component |

Testing Criteria |

|---|---|

|

Automatic tank gauges |

Test alarm, verify configuration, check battery |

|

Probes and sensors |

Inspect for buildup, test float movement, check cables |

|

Line leak detectors |

Simulate leak, verify activation within one hour |

|

Vacuum pumps/pressure gauges |

Confirm communication with sensors/controllers |

|

Handheld sampling equipment |

Ensure proper operation |

You must keep detailed records to demonstrate compliance. Maintain documentation of leak detection performance, maintenance, and calibration. Store annual test results for three years, manufacturer performance claims for five years, and site assessments for as long as methods are used. Retain records of repairs, upgrades, and operator training. Document financial responsibility and compatibility for regulated substances such as ethanol or biodiesel.

Tip: Accurate recordkeeping supports regulatory compliance and protects your business during inspections or audits. Detecting leaks early and maintaining proper documentation helps you avoid fines and environmental liability.

Detecting leaks early with advanced technologies like AI-powered sensors, wireless networks, and real-time monitoring protects your investment and the environment. You ensure reliable operation by scheduling regular maintenance, inspections, and testing of submersible pumps and leak detection systems. Annual updates to your leak detection program keep you compliant with evolving standards and industry best practices. Early detection reduces repair costs, extends equipment life, and supports operational efficiency for gas station operators and maintenance providers.

Staying proactive with maintenance and technology upgrades helps you avoid costly disruptions and maintain regulatory compliance.

FAQ

How often should you test leak detection systems in underground storage tanks?

You should test electronic and mechanical leak detection systems at least once every year. Regular testing ensures compliance with EPA and state regulations. Gas station equipment maintenance companies recommend scheduling annual inspections to verify system accuracy and operational safety.

What are the most reliable leak detection technologies for submersible pumps?

Automatic Tank Gauges (ATGs) and Continuous Statistical Leak Detection (CSLD) provide the highest reliability. These technologies offer real-time monitoring and early warning alerts. Fuel dispenser manufacturers and construction companies prefer these systems for their proven accuracy and regulatory compliance.

Can you integrate leak detection systems with existing submersible pumps?

You can integrate advanced leak detection systems with most submersible turbine pumps, including Red Jacket and 1.5hp models. Equipment maintenance providers recommend consulting your submersible pump supplier for compatibility and installation guidelines.

What records must you keep for regulatory compliance?

You must keep documentation of leak detection performance, annual test results, maintenance logs, and operator training records. Store these records for three to five years. Accurate recordkeeping helps you pass inspections and avoid penalties.

Why is early leak detection important for gas station operators?

Early leak detection protects your investment and reputation. You prevent environmental contamination, reduce cleanup costs, and maintain regulatory compliance. Construction companies and fuel dispenser manufacturers recommend proactive monitoring to minimize risk and ensure safe operations.