Description

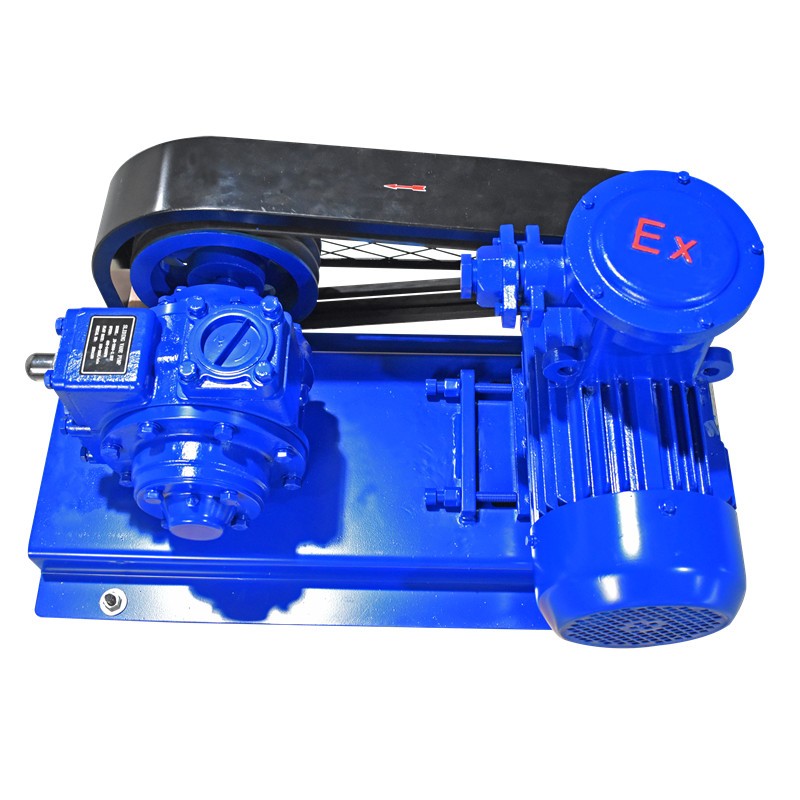

FUEL SUCTION PUMP BELT DRIVE PUMP ROTARY VANE PUMP KITS

YB-50/65/80 Rotary Vane Pump Kits (V-belt Driven) for Fuel Transfer

The YB series rotary vane pump kits, including models YB - 50, YB - 65, and YB - 80, are driven by V - belts. Specifically, the YB 80 series diesel transfer pumps, paired with 7.5kw explosion - proof motors, are designed for fuel transfer vehicles.

Function Highlights

The YB series pumps feature a unique vane design that can automatically adjust for wear, ensuring continuous performance and trouble - free operation. These pumps possess excellent self - priming capabilities, extended dry - running capacity, and can efficiently handle fluids with viscosities ranging from thin to thick. They are CE - certified, meeting EU safety standards, which guarantees market access and reliability.

Applications

Fleet Refueling: Ideal for quickly and efficiently refueling a fleet of vehicles.

Lubricating Oil Transfer: Suitable for handling lubricating oils in various industrial settings.

Aviation Refueling: Can be used in aviation refueling operations to transfer fuel safely and effectively.

Transport of Petrochemicals: Capable of transporting a wide range of substances such as gasoline, diesel, biofuels, solvents, and other petrochemical products.

Pump Structure and Working Principle

The YB series self - priming rotary vane pumps are equipped with a built - in bypass valve. The pump operates by using a rotor with sliding vanes to drive the liquid transfer. The construction material is nodular cast iron with self - lubricating vanes. Thanks to its high - performance design, the pump can handle both viscous and volatile liquids while requiring less horsepower compared to other equivalent pumps. It has a distinct advantage in achieving high flow rates at low revolutions.

Advantages

Durability and Quiet Operation: These pumps are built to last and operate quickly and quietly.

Reliable Performance: The sliding vane design ensures continuous performance and trouble - free operation, providing high reliability.

Safety Protection: An adjustable safety valve protects the pump from excessive pressure. A T - type filter can be used to protect the pumping system from damage caused by welding slag and other substances in the pipes and tanks.

Self - Adjusting Wear: The unique sliding vane pump design self - adjusts for wear, maintaining excellent self - priming and flow characteristics, eliminating the need for expensive starting systems.

Extended Dry - Running Capacity: The extended dry - running capacity eliminates the need for an interfering current monitoring system.

Easy Maintenance: The sliding vane design allows for easy blade replacement without removing the pump from the piping system.

High - Performance Transfer: The pumps have high suction lift and line - stripping capabilities, enabling complete emptying of tanks and efficient fluid transfer.

Low Cost of Ownership: With low maintenance requirements and a low lifecycle cost, the pumps are renewable and repairable.

Solid Handling Capability: Thanks to large displacement and slow internal speed, the pumps can handle solids.

Viscosity Flexibility: They can handle a wide range of fluid viscosities from thin to thick, eliminating the need for expensive heating systems.

Energy Efficiency: The efficient vane pumps require less horsepower, which means lower initial motor costs and reduced electricity consumption for powering the pump.

Installation

The pump can be installed on oil tank trucks using a cardan shaft or a hydraulic motor. It can also be installed on metal baseplates with a motor or a diesel engine, and is suitable for high - flow fuel dispensers and floating fuel equipment composed of pumps and flowmeters. When equipped with appropriate seals, the pump can also transfer a variety of solvents in the petrochemical industry.