Common Misconceptions About LC Positive Displacement Flow Meters

Common Misconceptions About LC Positive Displacement Flow meters: A Comprehensive Analysis

LC positive displacement (PD) Flow meters represent a remarkable advancement in fluid measurement technology. However, due to their distinctive design and operational principles, they are frequently subject to misunderstandings. This in - depth analysis aims to debunk the common misconceptions surrounding LC PD flow meters with technical details and industry insights.

1. Misconception: Frequent Maintenance is Necessary

Misunderstanding

There is a widespread assumption that PD meters, in general, demand regular lubrication and component replacement due to the inevitable wear and tear. People often associate mechanical movement with rapid deterioration of parts, believing that constant friction will lead to a short lifespan for the meter's components.

Reality

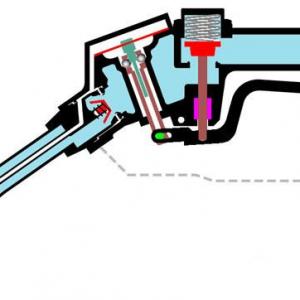

LC PD flow meters are engineered to minimize wear. By eliminating metal - to - metal contact within the measuring chamber, the risk of mechanical wear is virtually eradicated. The hydraulic sealing mechanism, which relies on a liquid capillary film (such as oil or the process fluid itself), acts as a self - lubricating system. Maintenance requirements are thus significantly reduced, primarily consisting of periodic checks of the sealing fluid level and register calibration, rather than the replacement of mechanical parts.

2. Misconception: Suitable Only for High - Pressure Systems

Misunderstanding

Traditional PD meter designs are often linked to high - pressure applications. This has led to the false belief that all PD meters, including LC ones, can only operate effectively under high - pressure conditions.

Reality

LC PD flow meters feature a low - pressure - drop design. Typically, they experience a pressure drop of less than 0.5 psi at rated flow. This makes them well - suited for gravity - fed systems. Moreover, the precise synchronization between the rotor and the housing ensures smooth operation even at low flow rates. As a result, they can be used in both pump - driven and low - pressure scenarios, greatly expanding their range of applicability.

3. Misconception: Limited to Specific Liquids

Misunderstanding

Users commonly think that LC PD flow meters are only capable of handling oils or fuels. This misconception stems from the historical use of PD meters in the petroleum industry.

Reality

These flow meters are highly versatile and can handle a wide variety of liquids. For viscous fluids, such as aviation fuel and lubricants with viscosities up to 1,000 cSt, they perform excellently. They can also measure low - viscosity fluids like water and solvents, provided that the appropriate sealing fluid is selected. Additionally, they can be used for adblue, corrosive liquids, and even in LPG gas - flow measurement applications. The capillary film adjusts to the properties of the fluid, ensuring reliable sealing across different applications.

4. Misconception: Sensitive to Installation Orientation

Misunderstanding

It is often thought that PD meters must be installed horizontally to prevent air entrainment. This idea is based on the assumption that gravity plays a crucial role in the proper functioning of the meter.

Reality

Thanks to the hydraulic sealing mechanism, LC PD flow meters can operate in any orientation. The rotating components are not affected by gravity, which makes them ideal for mobile applications. For example, they are commonly used in aircraft refueling trucks, where the meter may be installed at various angles during operation.

5. Misconception: Lack of Long - Term Accuracy

Misunderstanding

There is an assumption that wear and tear will gradually degrade the accuracy of PD meters over time. This concern is related to the general understanding that mechanical devices become less precise as they age.

Reality

The absence of metal contact and the minimal number of moving parts in LC PD flow meters ensure sustained accuracy. They typically maintain an accuracy of ±0.1% to ±0.5% of the reading. Long - term testing has shown negligible drift, and this accuracy is further validated by certifications such as OIML R 49 for custody transfer applications.

6. Misconception: Not Suitable for Harsh Environments

Misunderstanding

PD meters are often perceived as delicate and unable to withstand extreme temperatures or corrosive conditions. This view is based on the belief that the internal components of the meter are vulnerable to environmental factors.

Reality

LC PD flow meters offer great material flexibility. The housings can be made from materials such as stainless steel, Hastelloy, or PTFE, which are resistant to corrosion. The sealing fluids can be selected according to the operating temperature range, which can span from - 40°C to 150°C. Their rugged design allows them to be used in challenging environments such as offshore oil platforms and industrial plants, where they may be exposed to vibration and shock.

7. Misconception: Inability to Measure Intermittent Flows

Misunderstanding

It is commonly believed that PD meters require a continuous flow to provide accurate measurements. This misconception is based on the assumption that the counting mechanism in PD meters relies on a steady stream of fluid.

Reality

The unique rotor design of LC PD flow meters, which consists of blocking and displacement rotors, enables accurate counting even with pulsating or bidirectional flows. Applications in batch processing and pump - driven systems have proven their effectiveness in measuring intermittent flows.

Conclusion: Leveraging LC PD Flow Meters with Confidence

LC positive displacement flow meters break away from the limitations of traditional PD meters through their innovative design. By understanding their unique features, such as hydraulic sealing, low wear, and adaptability, users can confidently apply them across a wide range of industries, from aviation to food processing. It is always advisable to consult the manufacturer's guidelines for specific information regarding fluid compatibility and installation requirements to ensure optimal performance.

JIAHAO Product Introduction

JIAHAO is a supplier of high - quality liquid and gas measurement flowmeters and accessories in the LC series. These flowmeters adopt Liquid Controls' unique positive displacement metering principle, providing extremely accurate service even under variable operating conditions (changes in temperature, pressure, and viscosity).

Typical Applications

They cover various fields such as adhesives, agriculture, chemicals, asphalt, animal feed, aviation fuel, beverages, concrete, additive mixtures, cosmetics, crude oil, dairy products, fuel, fuel oil, industrial chemicals, liquid fertilizers, liquefied gas, lubricants, paints and varnishes, printing inks, processed foods, and refined petroleum products.

Product Advantages

High Precision and Repeatability: They can provide accurate and consistent measurement results under various complex working conditions.

Low Maintenance: There is no metal - to - metal contact in the measuring chamber, reducing mechanical wear and lowering maintenance costs and frequency.

Low Pressure Drop: They are true gravity flow meters with small pressure loss, suitable for gravity - fed systems.

Diverse Material Selection: There are various materials such as aluminum, cast iron, and stainless steel to choose from to adapt to different application environments and fluid characteristics.

Operational Independence: Units equipped with mechanical recorders, printers, or preset devices can operate independently without the need for electricity or signal conditioning, and there are no special pipeline requirements.

Optional Electronic Functions: In cases where higher precision and electronic communication are required, electronic output and recording devices can be provided.