Vapor Recovery Nozzles: Fueling Green Stations

Harnessing Vapor Recovery: How Vapor Recovery Nozzles Form the Cornerstone of Fuel Station Environmental Compliance and Profitability

In an era of increasingly stringent environmental regulations, controlling fuel vapor emissions at gas stations has become a paramount industry concern. As a production enterprise specializing in the research and development of environmental protection equipment for fuel stations, we understand the critical role of vapor recovery technology in safeguarding environmental quality and boosting operational efficiency. Among these technologies, the vapor recovery nozzle stands out as a pivotal component of the Vapor recovery system; its performance directly impacts recovery efficiency, user experience, and overall environmental outcomes.

This article will delve into the core value of Vapor recovery systems, emphasizing the decisive role of the vapor recovery nozzle. We'll also detail our company's extensive product portfolio in vapor recovery, including advanced online monitoring systems, a comprehensive secondary vapor recovery product chain, and highly efficient tertiary vapor recovery treatment devices. Our aim is to provide you – fuel equipment suppliers, gas station operators, environmental equipment procurement managers, and all partners interested in green energy solutions – with comprehensive insights to help you strike the perfect balance between environmental responsibility and profitability.

I. Vapor Recovery: Why It's Crucial for Modern Fuel Stations

Fuel vapors, primarily volatile organic compounds (VOCs) that evaporate during gasoline storage, transport, and dispensing, are not only atmospheric pollutants harmful to human health but also valuable lost energy. Vapor recovery technology was developed to capture and treat these volatile emissions, reducing environmental pollution while recovering energy for economic benefit.

Vapor recovery systems typically operate in three stages:

-

Vapor Recovery Stage Ⅰ: Occurs when fuel tankers unload gasoline into station storage tanks. Vapors from the storage tank are returned to the tanker via sealed lines.

-

Vapor Recovery Stage Ⅱ : Happens during vehicle refueling. Specialized equipment collects vapors displaced from the vehicle's fuel tank and returns them to the gas station's underground storage tanks. This is the main focus of this article, with the vapor recovery nozzle being a core component.

-

Vapor Recovery Stage Ⅲ: Provides further deep treatment for any residual vapors that weren't captured or processed by the secondary recovery system, ensuring compliance with even stricter emission standards.

II. The Vapor Recovery Nozzle: Guardian of the "Last Mile" in Secondary Vapor Recovery

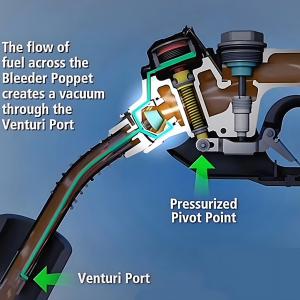

In the secondary vapor recovery system, the vapor recovery nozzle is the crucial device that directly connects to the vehicle's fuel tank and performs the task of vapor capture. Its design and performance directly determine the efficiency of vapor recovery and the overall fueling experience.

Distinguishing Traditional Fuel nozzles from Vapor Recovery Nozzles:

A traditional Fuel nozzle is designed solely for dispensing fuel. In contrast, a vapor recovery nozzle features a unique coaxial (double-channel) design that simultaneously dispenses fuel and draws displaced vapors from the vehicle's tank back into the recovery line.

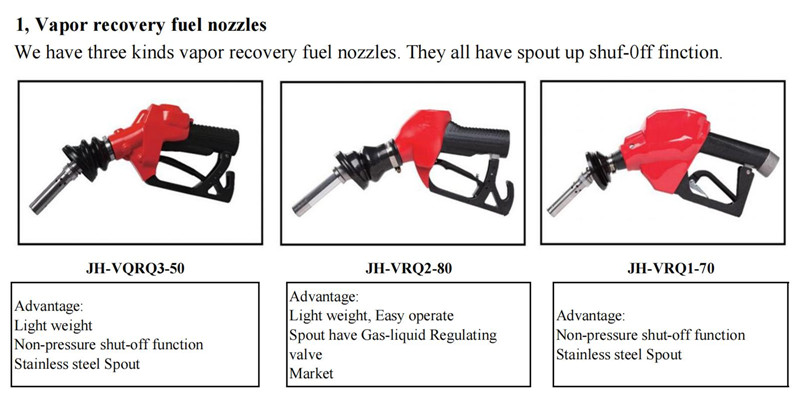

Our Strengths in Vapor Recovery Nozzles:

Our company boasts four models of vapor recovery nozzles, including two self-developed and patented designs. These nozzles offer significant advantages:

-

High Efficiency: Precision fluid dynamic design ensures maximum capture of volatile fuel vapors during the fueling process, leading to high recovery rates.

-

User-Friendly Operation: Ergonomically designed, lightweight, and easy to grip, allowing for smooth fueling and reducing operator fatigue.

-

Safety and Reliability: Equipped with multiple safety mechanisms, such as automatic shut-off, overflow prevention, and robust valve systems, effectively preventing fuel spills and accidents.

-

Durability: Made from high-quality materials and utilizing advanced manufacturing processes, our vapor recovery nozzles withstand the high-intensity, long-duration usage typical of fuel stations, reducing maintenance frequency and costs.

-

Excellent Compatibility: Our vapor recovery nozzles are designed to meet mainstream vehicle fuel port standards, ensuring broad applicability across different car models.

These characteristics make our vapor recovery nozzles more than just dispensing tools; they are instruments for environmental protection and enhancers of fuel station operational efficiency.

III. Comprehensive Solutions: Our Full Vapor Recovery Product Chain

As a specialized manufacturer of environmental protection equipment, we offer complete vapor recovery solutions that cover every stage, from monitoring and recovery to deep treatment.

1. Vapor Recovery Online Monitoring System:

Real-time monitoring is the foundation of efficient management. Our Vapor Recovery Online Monitoring System precisely measures critical parameters like flow rate, pressure, and concentration in the vapor recovery pipeline, ensuring system compliance. This system incorporates high-accuracy Gas Roots Flowmeters, providing precise data to help fuel station managers promptly identify and resolve issues, preventing excessive emissions.

2. Secondary Vapor Recovery System: A Complete Product Chain, Secondary vapor recovery is one of our core product lines. Beyond the vapor recovery nozzles detailed above, we also provide:

-

Vapor Recovery Pumps: As the power core of the vapor recovery system, these pumps are responsible for drawing collected vapors back into the storage tanks. We offer five models of vapor recovery pumps, including:

-

Dur Vapor Recovery Pump: Stable performance and reliable operation, suitable for standard conditions.

-

NP Frequency Pump: Utilizes variable frequency technology to intelligently adjust speed based on demand, offering energy efficiency and extending equipment life.

-

Explosion-Proof High-Flow Vapor Recovery Pump: Designed for high-volume gas stations or specific requirements, ensuring fast and efficient recovery.

-

Scraper-Type Vapor Recovery Pump: Offers excellent self-priming capability and adaptability to complex operating conditions.

-

Piston-Type High-Vacuum Vapor Recovery Pump: Provides a higher vacuum degree for more thorough vapor recovery.

-

-

Vapor Recovery Hose: Specialized composite hoses ensure the airtightness and safety of vapor transfer.

-

Vapor Recovery Breakaways (Separation Joints): In the event of a vehicle accidentally driving off, these devices automatically separate and shut off both fuel and vapor lines, preventing equipment damage and fuel spills, ensuring site safety.

-

Vapor Recovery Detector: Provides real-time monitoring for vapor leaks, offering timely warnings to prevent incidents.

By offering a complete range of products, from vapor recovery nozzles to vapor recovery pumps, hoses, and safety breakaways, we build a comprehensive secondary vapor recovery product chain for our clients, ensuring efficient, safe, and reliable system operation.

3. Tertiary Vapor Recovery Treatment Devices: For fuel stations requiring even stricter emission standards, we offer advanced tertiary vapor recovery treatment devices:

-

JH-TL20 Condensation + Carbon Adsorption Series: Combines condensation technology to remove the majority of vapors, followed by activated carbon adsorption for further purification, ensuring emissions meet stringent limits.

-

JH-ML100 Air-Cooled + Membrane Separation Series: Employs advanced membrane separation technology for deep vapor separation and recovery, suitable for locations with extremely high emission requirements.

These treatment devices purify even trace amounts of vapors not captured by secondary recovery, elevating environmental standards to a new level.