DEF Management: Smart Tanks, Pumps & Metering

Mastering Clean Emissions: How DEF Fluid Storage, Pumping & Metering Solutions Empower Your Business

In today's world of advanced diesel engine technology, Diesel Exhaust Fluid (DEF) has become an indispensable component for heavy-duty diesel vehicles, agricultural machinery, mining equipment, and even some industrial applications. As emission regulations grow stricter, the efficient, safe storage, pumping, and precise metering of DEF are becoming critical industry demands. For fuel equipment suppliers, lubricant solution providers, industrial and automotive aftermarket suppliers, and various specialized fluid handling companies, understanding and offering superior DEF fluid tank and pump systems, DEF fluid tanks and pumps, standalone DEF pumps, DEF nozzles, and DEF Flow meters will be key to expanding markets, addressing customer pain points, and achieving business growth.

This article will dive deep into the essential elements of DEF solutions and their value in different application scenarios. Our goal is to provide your potential customers with comprehensive, in-depth insights, helping them choose the most suitable DEF handling equipment to ensure compliant vehicle and equipment operation while optimizing costs and boosting operational efficiency.

I. DEF: The Cornerstone of Clean Diesel Power

DEF is a non-toxic solution made from high-purity urea and deionized water. It works within Selective Catalytic Reduction (SCR) systems to convert harmful nitrogen oxides (NOx) from diesel engine exhaust into harmless nitrogen gas and water vapor. With increasing global environmental awareness and the enforcement of stricter emission regulations (like Euro V, Euro VI, EPA 2010), DEF consumption continues to rise, driving up demand for related infrastructure.

Effective DEF management isn't just about compliance; it's also about:

-

Ensuring Vehicle Operation: Lack of DEF or poor-quality DEF can cause engine derating or prevent vehicles from starting.

-

Extending SCR System Life: Pure DEF and precise injection protect the SCR system from crystallization and corrosion.

-

Optimizing Operating Costs: Accurate metering and efficient dispensing prevent DEF waste, helping control procurement and maintenance costs.

II. DEF Fluid Tanks and Pump Systems: Building the Foundation for Efficient Supply

A complete DEF supply solution relies on reliable and efficient DEF fluid tank and pump systems. These systems are designed to safely store DEF and transfer it from the storage point to vehicles or equipment.

1. DEF Fluid Tanks: Key to Safe DEF Storage DEF has specific storage requirements: it must not be exposed to direct sunlight or contamination, as these can compromise its purity and performance. Therefore, specialized DEF tanks feature:

-

High-Quality Materials: Typically made from Polyethylene (PE) or stainless steel, ensuring chemical compatibility with DEF to prevent corrosion and contamination.

-

UV Protection: Dark or opaque designs to prevent DEF degradation caused by direct sunlight.

-

Temperature Control (Optional): In extremely cold regions, heating elements may be required to prevent DEF from freezing (DEF freezing point is around -11°C / 12°F), ensuring normal supply in any environment.

For fuel equipment suppliers and distributors, offering DEF fluid tanks of various capacities—from small portable tanks to large fixed installations—can meet the diverse storage needs of truck fleets, farms, construction sites, and industrial parks.

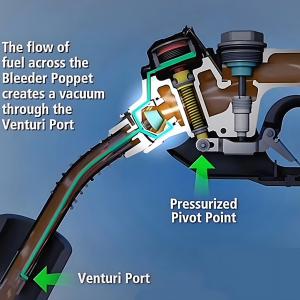

2. DEF Pumps: The Power for Precise and Efficient Transfer The DEF pump is the heart of the entire system, responsible for drawing DEF from the tank and transferring it to the dispensing point. Due to DEF's characteristics (e.g., corrosiveness, sensitivity to impurities), the choice of DEF pump is crucial:

-

Specialized Materials: The pump body, impeller, and seals must be made from materials compatible with DEF, such as stainless steel or engineered plastics.

-

Self-Priming Capability: Many DEF pumps have good self-priming capabilities, making it easy to draw liquid from ground-level tanks or containers.

-

Flow Rate and Pressure: Select appropriate flow and pressure parameters based on application needs. For example, high-flow pumps are needed for large fleet refueling, while lower-flow pumps might suffice for smaller equipment.

-

Reliability: Long-term stable operation reduces failure rates and ensures uninterrupted supply.

As a provider of lubrication equipment and fluid handling solutions, offering high-performance DEF pumps—such as electric, pneumatic, or hand pumps—can meet your customers' diverse DEF transfer needs, whether for fixed dispensing stations or mobile solutions.

III. Precise Dispensing and Metering: The Core Role of DEF Nozzles and DEF Flow meters

At the terminal end of the DEF supply chain, precise dispensing and metering are vital, directly impacting user experience, cost control, and compliance.

1. DEF Nozzles: Convenient and Safe End-Point Interface The DEF nozzle is the direct interface for users, and its design directly influences the convenience and safety of dispensing:

-

Automatic Shut-off: Similar to Fuel nozzles, it automatically stops dispensing when the DEF tank is full, preventing spills and protecting the vehicle and environment.

-

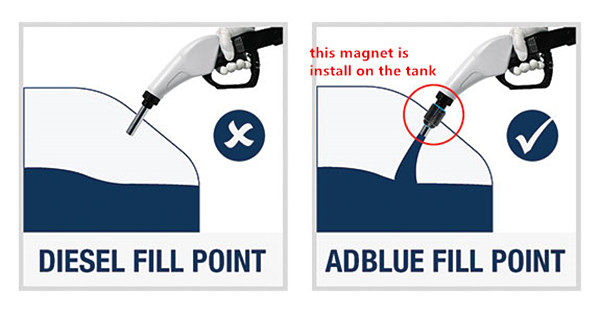

Mis-filling Prevention: DEF fill points typically have specific sizes and magnetic identification designs to prevent accidentally filling with diesel or other liquids, protecting the SCR system. Therefore, the DEF nozzle's tip size must also comply with industry standards.

-

Compatible Materials: Parts that come into contact with DEF must be made from stainless steel or specialized plastics.

-

Ergonomic Design: Lightweight and easy to grip, reducing operator fatigue.

For industrial and automotive aftermarket suppliers, providing DEF nozzles compatible with various vehicle and equipment interfaces is a crucial part of meeting customer maintenance and service needs.

2. DEF Flow Meters: Guardians of Accurate Measurement Whether for wholesale, retail, or internal consumption, accurate DEF metering is indispensable. The DEF flow meter plays a critical role:

-

High-Accuracy Measurement: Utilizing technologies like positive displacement, turbine, or Coriolis mass flow meters, they ensure the accuracy of DEF metering, which is especially important for custody transfer (buyer-seller settlement).

-

Data Visualization: Integrated digital displays intuitively show current flow rate, total volume, and accumulated volume, making it easy for operators to read.

-

Data Output Capabilities: Provide pulse signals, RS485, or Modbus interfaces to transmit metering data to management systems, POS terminals, or vehicle management systems for remote monitoring, inventory management, and report generation.

-

Corrosion Resistance: Components in contact with DEF must be made from high-grade stainless steel or DEF-specific plastics to ensure long-term stable operation without corrosion.

For companies with specific fluid handling needs, such as mining fuel transport companies or agricultural chemical distributors, the precision of DEF flow meters helps them effectively manage DEF consumption, prevent waste, optimize operating costs, and meet environmental regulations for metering.

IV. Comprehensive Solutions: DEF Fluid Tank and Pump Systems in Various Industries

Integrated DEF fluid tank and pump system solutions offer immense value across different industries:

-

Large Fleets and Logistics Companies: Establish in-house DEF dispensing stations equipped with large-capacity DEF fluid tanks, high-flow DEF pumps, and dispensing nozzles with integrated flow meters, enabling convenient and economical bulk refueling, reducing external procurement costs and fueling time.

-

Farms and Construction Sites: Mobile or portable DEF fluid tank and pump systems facilitate on-site refueling in remote locations, ensuring continuous operation of agricultural machinery and construction vehicles.

-

Gas Stations and Retail Networks: DEF dispensing modules integrated alongside Fuel pumps offer standardized retail refueling services, meeting the daily needs of diesel vehicle owners.

-

Industrial Facilities and Generator Sets: Provide dedicated DEF fluid tank and pump systems for stationary diesel generators or industrial equipment, ensuring they meet emission standards and operate reliably.

-

Automotive Service and Repair Centers: Offer small to medium-sized DEF tanks and DEF pumps, coupled with DEF nozzles and DEF flow meters, for routine maintenance and DEF top-ups during repairs.

V. Choosing the Right DEF Solution: Key Considerations

Selecting high-quality DEF handling equipment is fundamental to ensuring long-term efficient operation and compliance. When purchasing DEF fluid tanks and pumps, DEF pumps, DEF nozzles, and DEF flow meters, consider the following:

-

Material Compatibility: Ensure all components in contact with DEF are made from compatible materials (e.g., PE, 304/316 stainless steel) to prevent contamination and equipment damage.

-

Flow Rate and Pressure Needs: Choose pumps and dispensing systems with appropriate flow and pressure ratings based on your dispensing speed and equipment requirements.

-

Accuracy: For commercial metering or strict internal management, selecting systems with high-precision DEF flow meters is crucial.

-

Environmental Adaptability: Consider the operating environment's temperature range, especially whether heating functions are needed in cold regions.

-

Safety Features: Check if the system includes safety features like spill prevention, dry-run protection, and emergency stops, and if it complies with relevant safety standards.

-

Ease of Use and Maintenance: Choose equipment that is simple to operate, easy to maintain, and clean.

-

Brand Reputation and Technical Support: Prioritize suppliers with a good reputation who offer reliable after-sales service and technical support.

Conclusion: Empowering Clean Emissions, Building an Efficient Future

As global focus on environmental protection and emission regulations intensifies, DEF has evolved from an emerging product into an indispensable part of the diesel power sector. For your customer base—whether they are fuel equipment distributors, lubricant specialists, aftermarket suppliers, or specialized fluid handling enterprises—providing comprehensive, reliable DEF fluid tank and pump systems, high-quality DEF pumps, safe DEF nozzles, and precise DEF flow meters will be key to standing out in the market.

Investing in professional DEF solutions not only helps customers meet compliance requirements but also optimizes their operations and reduces waste, leading to sustainable development and long-term benefits. We are committed to being your trusted partner in DEF solutions, jointly advancing clean emission technologies.