What Happens When You Heat Urea?

The Real Reason Your DEF Fluid Crystallizes and Clogs Your Engine

Introduction: The Unseen Threat to Your Diesel Engine

Every truck driver, fleet manager, and equipment operator knows the importance of DEF (Diesel Exhaust Fluid). It's the key to clean-running engines and staying compliant with strict emissions regulations. But what happens when this crucial fluid turns from a helpful liquid into a damaging solid? This is a common and costly problem that can lead to clogged injectors, expensive repairs, and frustrating engine breakdowns.

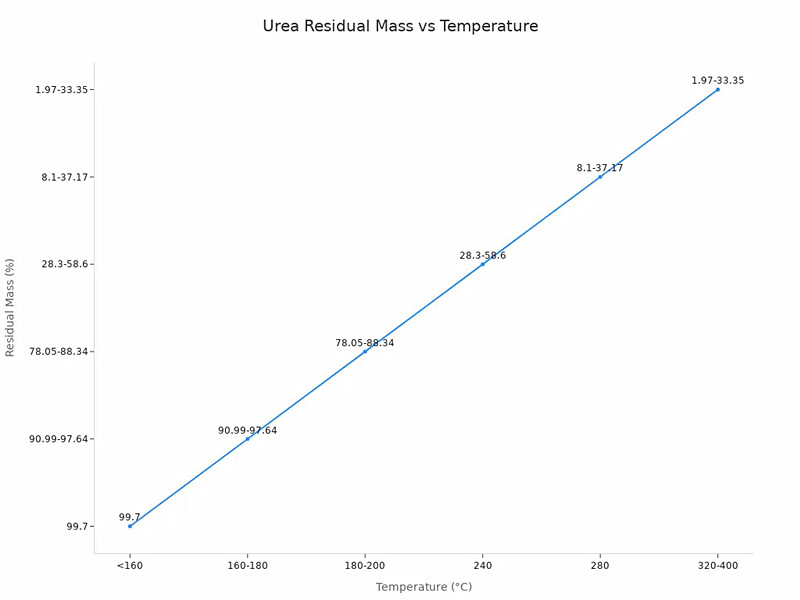

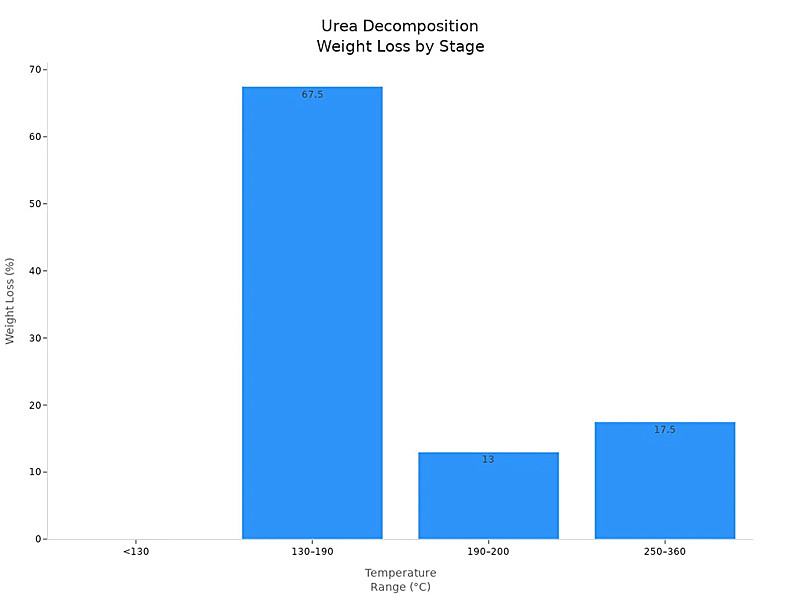

The answer lies in the very substance that makes up DEF: AdBlue urea. When exposed to heat, AdBlue urea undergoes a series of chemical changes that can create a silent but deadly threat to your entire SCR (Selective Catalytic Reduction) system. This guide will demystify what happens when you heat urea, revealing the science behind why your DEF diesel exhaust fluid urea can go bad, and most importantly, how to prevent it from happening to you.

1. The First Signs of Trouble: Why Your DEF Fluid Starts to Change

You've probably noticed that DEF fluid looks just like water—clear and colorless. But its stability is a mirage. When it’s exposed to heat, the first thing that happens is a simple physical change: it gets warmer. The real problems begin when the temperature rises above the ideal range.

From Liquid to Gas: The Beginning of Breakdown

The primary component of DEF fluid is urea, which has a melting point of around 133–135 ºC. In a healthy engine's SCR system, the hot exhaust gases vaporize the DEF diesel exhaust fluid urea to release ammonia, which then does its job of neutralizing harmful pollutants. This is the good kind of heat.

However, if your DEF fluid is stored or handled improperly—for example, in a hot fuel tank on a sun-beaten oil tanker, or a dispensing unit at a gas station exposed to direct sunlight—it starts to break down. Even small amounts of heat over a long period can begin this process. The urea molecule starts to split, releasing ammonia gas and another chemical called isocyanic acid. This is the start of the bad kind of heat.

Key Takeaway for Drivers & Fleet Managers: That sharp, distinctive smell of ammonia you sometimes catch a whiff of around your DEF tank is a red flag. It's a sign that your AdBlue urea is already breaking down, and its effectiveness is diminishing.

2. The Hard Truth: How Heat Turns Your DEF into a Solid Problem

The real danger begins when the temperature rises even higher, accelerating the breakdown of urea diesel. This is where the unseen, insidious process of crystallization begins.

The Science of Crystallization: What Forms in Your Pipes

Once urea breaks down, its byproducts (like isocyanic acid) don’t just disappear. If the system's temperature is too low to properly vaporize the DEF, these byproducts can react with each other to form new, unwanted compounds. The most notorious of these is biuret.

Biuret is a solid, crystalline substance. It’s what happens when heat and improper conditions get the best of your DEF fluid. This hard, white or yellowish deposit is a major problem for everyone from agriculture and construction fleets to mining operations and forecourt maintenance companies. These deposits build up in the most critical parts of your SCR system, including:

-

DEF Injector Nozzles: A single clogged nozzle can prevent DEF from being properly sprayed into the exhaust stream.

-

The SCR Catalyst: Deposits can coat the catalyst's honeycomb structure, rendering it useless and causing a major drop in performance.

-

Pipes and Lines: These deposits act like cholesterol in a vein, restricting fluid flow and increasing pressure.

Why This Matters for Your Business:

-

High Repair Costs: A clogged SCR system can cost thousands of dollars to repair or replace.

-

Vehicle Downtime: A vehicle with a derated engine or a failed SCR system is out of commission, leading to lost revenue and missed deadlines.

3. The Temperature Danger Zone: A Simple Guide to Safe DEF Handling

Understanding the temperature ranges for DEF fluid is key to preventing these costly issues. You can think of it in clear, simple stages:

-

Below 10°C (50°F): This is the ideal storage temperature. In this range, DEF fluid can last for up to 36 months, allowing for long-term storage in an oil depot or a garage.

-

Above 35°C (95°F): This is the danger zone. At these temperatures, DEF fluid's shelf life plummets to just a few months. This is a major concern for oil tanker parts and gasoline station construction companies that might store DEF in hot, unshaded environments.

-

Freezing is Not a Problem! Many people worry about DEF fluid freezing at 12°F (-11°C). But vehicle systems are designed to handle this with heated tanks and lines. The real enemy is heat, not cold.

Practical Tips to Avoid Contamination & Crystallization:

-

Store It Cool: Keep your bulk DEF fluid in a cool, shaded place. If you're a fueling station owner, ensure your DEF dispenser tanks are insulated or protected from direct sunlight.

-

Use the Right Equipment: Never use a nozzle or a hose that has been in contact with diesel fuel or other chemicals. This is a sure-fire way to contaminate your AdBlue urea and render it useless.

-

First-In, First-Out (FIFO): For fleet managers and agricultural suppliers, always use your oldest stock first to prevent it from expiring on the shelf.

4. Beyond the Basics: The Ultimate Guide to Protecting Your Investment

Beyond simple temperature control, a few more advanced practices can ensure the long-term health of your diesel equipment.

Check for Purity: A Simple Test

A simple visual check is a good start, but for larger operations, a refractometer is a wise investment. This tool precisely measures the urea concentration in your fluid. The optimal range is 32.5%. If the reading is off, you know your DEF fluid has been compromised and should be replaced.

Educate Your Team

For fueling equipment manufacturers and fueling station maintenance companies, educating clients is the best form of preventative maintenance. Teach your customers the difference between a fuel tank and a DEF tank and the severe consequences of mixing them. Highlight the risks of using expired or contaminated fluid.

Invest in Quality Equipment

The right DEF transfer and dispensing equipment is your best defense against contamination. Invest in sealed, dedicated DEF pumps and nozzles that are made from ISO-certified materials. These are designed to protect the purity of the urea diesel and prevent costly mistakes.

Concerned about urea heating effects? We supply durable urea handling equipment and solutions—for trucks, agricultural machinery, mining vehicles, and refueling systems.

Conclusion: From Knowledge to Action

Understanding what happens when you heat urea is more than just a science lesson—it's a critical part of modern diesel engine maintenance. The silent process of crystallization can lead to major headaches, from frustrating breakdowns to thousands of dollars in repairs.

By being mindful of temperature, preventing contamination, and using the right equipment for your fueling station or industrial operation, you can ensure your DEF fluid remains clean and effective. Protect your investment, reduce downtime, and keep your engines running smoothly for the long haul.