What Does Water in Diesel Fuel Look Like?

When water is present in diesel fuel, you might observe a few typical appearances:

1. Free Water

This is the easiest form of water to identify. Since water is heavier than diesel and doesn't mix with it, any excess water will separate and settle at the bottom of the fuel tank.

-

Key Visuals:

-

Distinct Layers: If you let a diesel sample sit in a clear container, the water will clearly form a separate, visible layer at the bottom, beneath the diesel. The diesel itself will still look like a normal clear yellow or brownish liquid.

-

Visible Droplets: You'll directly see obvious beads or puddles of water at the bottom of your fuel tank or in the collection bowl of your fuel filter.

-

Color: The water itself is clear, but it might appear brown, black, or even milky if mixed with fuel contaminants, rust, or microbial growth.

-

2. Emulsified Water

This occurs when water is finely dispersed throughout the diesel fuel in tiny droplets, forming a stable mixture. This emulsification usually happens due to high-speed agitation within the fuel system, certain fuel additives, or biological contamination.

-

Key Visuals:

-

Cloudy or Milky Appearance: The diesel won't be clear anymore. Instead, it will look cloudy, hazy, milky white, or grayish, sometimes resembling "coffee with milk" or "dishwater." This is because light scatters off the suspended water droplets, making the fuel opaque.

-

Difficult to Separate: Even after sitting for some time, emulsified water will separate very slowly or not at all, as the water droplets are extremely small and uniformly dispersed.

-

3. Dissolved Water

All diesel fuel naturally contains a small amount of dissolved water, much like air contains humidity. These water molecules are fully dissolved and cannot be seen with the naked eye. Dissolved water only becomes free water or emulsified water when its concentration exceeds the fuel's saturation point.

-

Key Visuals: Not visually detectable. The diesel will appear perfectly normal and clear. Only specialized water content tests can identify dissolved water.

How to Deal With Water in Diesel Fuel

Dealing with water in diesel fuel is crucial for your engine's health. The approach depends on the form of water and the level of contamination.

1. Detection and Routine Handling

-

Regularly Check Fuel Filter Water Separator Bowls: Most diesel vehicles have a fuel-water separator (often a primary filter) with a clear bowl at the bottom and a drain valve. Drivers should routinely (e.g., daily or before refueling) check and drain any accumulated water from this bowl. This is the simplest and most vital daily maintenance step, forming a cornerstone of effective fuel management.

-

Sample and Observe: Draw a small fuel sample from the bottom of your fuel tank or before the fuel filter into a clean, clear container. Let it sit, then carefully observe for water layers, droplets, or milky discoloration.

2. Removing Existing Water

-

Drain Fuel Tank Bottoms: If your fuel tank has a drain plug or a designated drain point, you can periodically drain accumulated water from the tank bottom. This is especially effective for removing large amounts of free water. When performing this, ensure your fuel hose is clean and the procedure is followed correctly to avoid introducing new contaminants.

-

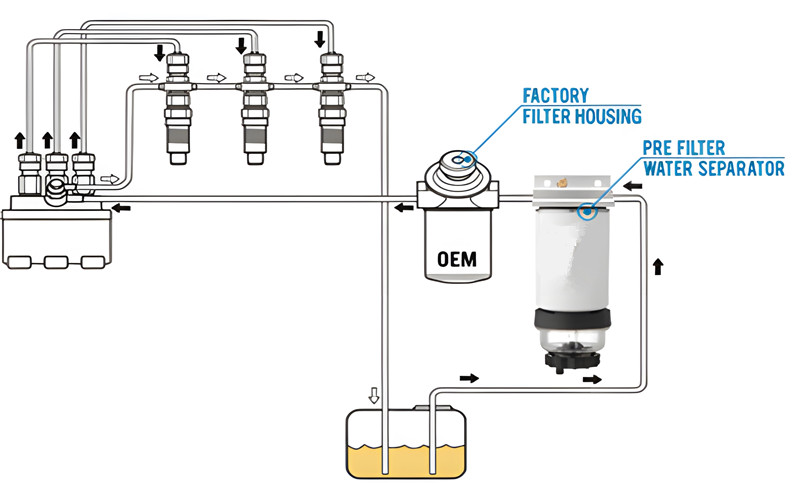

Utilize High-Efficiency Water Separators/Coalescers: While your vehicle's existing fuel-water separator is good for free water, for stubborn emulsified water, you might need higher-efficiency coalescing filters. These specialized filters use media that encourage tiny water droplets to combine into larger ones, allowing them to settle out. For some vehicles, upgrading your filtration system might involve a fuel filter adapter to fit more advanced or higher-capacity filters.

-

Chemical Treatments:

-

Water Demulsifiers: Certain fuel additives act as demulsifiers, helping to break down emulsified water into larger droplets so they can separate and be drained. Always follow product instructions carefully.

-

Biocides: If microbial contamination (diesel bug/algae) is present (often signaled by slimy black residue in filters or fuel), water is the culprit. You'll need specific biocides to kill the microorganisms. After treatment, it's vital to drain dead microbial matter and potentially use an upgraded diesel Fuel pump filter or secondary filter to prevent re-contamination.

-

-

Professional Fuel Polishing/Cleaning: For severe contamination in large tanks or equipment, professional fuel management services are the best solution. They use specialized filtration, coalescing, and circulation equipment, often involving high-capacity fuel transfer pumps and multi-stage diesel Fuel pump filters, to thoroughly remove water, sediment, and microbial growth.

3. Prevention: Building a Robust Fuel Management System

Prevention is always better than cure. Implementing effective fuel management practices significantly reduces the risk of water in your diesel fuel.

-

Source Quality Fuel: Always purchase diesel from reputable suppliers who maintain high standards for fuel cleanliness and storage.

-

Proper Fuel Storage:

-

Keep your fuel storage tanks clean and regularly check and drain any accumulated water from their bottoms.

-

Ensure tanks are sealed to prevent rainwater, humidity, or condensation from entering.

-

Store tanks with a slight incline to allow water to collect at a specific drain point.

-

Avoid leaving tanks empty for extended periods, which increases condensation.

-

-

Use Clean Transfer Equipment:

-

Any fuel hose used for fueling or transferring diesel must be kept clean, free from damage, and regularly inspected.

-

Your fuel transfer pump and its associated piping and filters must also be routinely maintained and cleaned to ensure they don't introduce water or contaminants during the transfer process. A well-maintained fuel transfer pump with an integrated diesel fuel pump filter can be a powerful first line of defense during refueling.

-

-

Regular Vehicle Fuel System Maintenance:

-

Adhere strictly to manufacturer recommendations for replacing fuel filters and water separator elements.

-

In cold weather, pay extra attention to signs of fuel system icing and ensure heating elements (like filter heaters) are working correctly.

-

Consider using an appropriate fuel filter adapter to upgrade or optimize your existing filtration system for improved water separation efficiency.

-

By understanding the different forms of water in diesel, implementing appropriate treatment methods, and maintaining a proactive fuel management system that includes clean fuel hose, reliable fuel transfer pumps with efficient diesel fuel pump filters, and the strategic use of fuel filter adapters, you can significantly mitigate the risk of engine issues and ensure the long-term, reliable operation of your vehicles and equipment.