How Fuel Flow Meters Guarantee Accurate Gas Station Pumping?

Gas station fuel measurement accuracy is a significant concern for consumers, involving various technical, regulatory, and management factors.

1. How Fuel Flow meters Work

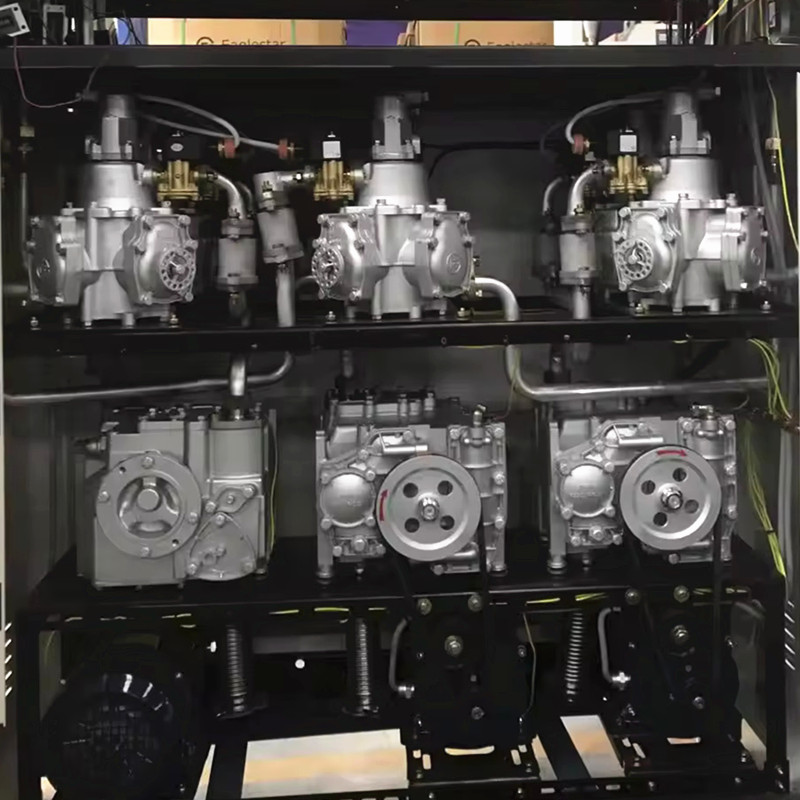

Fuel Flow meters are the core components of fuel dispensers, responsible for precisely measuring the volume of fuel delivered. Common measurement technologies include:

-

Positive Displacement Flowmeter (PD Flowmeter): This is the most commonly used type in gas stations. It precisely measures and discharges a fixed volume of fuel through a series of accurately machined chambers (e.g., pistons, rotors, or gears). Each time these chambers fill and empty, a fixed volume unit is recorded. PD flowmeters offer high accuracy and are less affected by fluid viscosity.

-

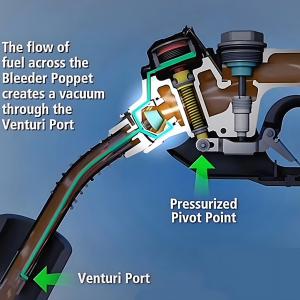

Turbine Flowmeter: As fuel flows through the meter, it spins an internal turbine. The turbine's rotational speed is directly proportional to the fuel's flow rate. By measuring the turbine's frequency, the fuel's flow rate can be calculated.

-

Mass Flowmeter: This type of flowmeter directly measures the mass of the fuel, rather than its volume. Coriolis mass flowmeters, a common type, determine mass flow by measuring the Coriolis force generated by the fluid in a vibrating tube. Mass flowmeters are advantageous because they are unaffected by temperature and pressure changes that cause volumetric expansion or contraction, making them more common in applications requiring high precision or in regions where fuel is sold by mass.

Accuracy Differences: Electronic vs. Mechanical Fuel Flowmeters:

-

Mechanical Flowmeters: These rely primarily on mechanical components (e.g., gears, counters) for measurement and display. They are relatively simple in structure and lower in cost, but their accuracy can be affected by wear over long-term use.

-

Electronic Flowmeters: These incorporate electronic sensors and microprocessors in addition to mechanical measurement. They convert mechanical motion into electrical pulse signals, displaying the measurement results on an electronic screen. Electronic flowmeters generally offer higher accuracy, better stability, and enhanced anti-tampering capabilities, often including advanced features like temperature compensation. Modern fuel dispensers predominantly use electronic flowmeters.

2. Regulation and Standards for Gas Station Measurement Accuracy

To ensure the accuracy of gas station measurements, countries worldwide have established strict regulatory systems and standards.

-

International and National Standards:

-

NTEP Certification (National Type Evaluation Program) in the USA: NTEP is a program under the U.S. National Institute of Standards and Technology (NIST) that evaluates and certifies the accuracy and consistency of commercial weighing and measuring devices. Fuel dispensers must obtain NTEP certification before being sold in the U.S. market.

-

Europe (MID Directive): The European Union's Measuring Instruments Directive (MID - 2014/32/EU) sets out essential requirements and conformity assessment procedures for measuring instruments, ensuring that those sold in the EU market comply with unified standards.

-

China's Metrological Requirements: In China, fuel dispensers are mandatory verification measuring instruments and must undergo regular verification by local market supervision and administration departments (or their authorized metrological verification institutions). They can only be used after passing verification.

-

Middle East Metrological Requirements: Middle Eastern countries generally refer to international standards or establish their own national standards, strictly regulating the measurement accuracy of fuel dispensers. For example, the Saudi Standards, Metrology and Quality Organization (SASO) also has clear requirements for fuel dispenser accuracy.

-

-

How to Confirm a Fuel Dispenser is Compliant; How Consumers Can Check Verification Labels:

-

Verification Labels/Seals: Compliant fuel dispensers usually display a verification certificate in a prominent location, indicating the verification date, validity period, and verifying authority. Additionally, key parts (such as the metering adjustment device) will have lead seals or tamper-evident stickers to prevent unauthorized alterations. If a seal is broken or a verification label is missing, consumers have reason to question its accuracy.

-

Display Screen Reset: Before fueling, always ensure that the amount and volume on the fuel dispenser's display screen have both reset to zero.

-

3. Potential Fraudulent Methods for Fuel Flow Meters

Despite strict regulations, a few unscrupulous individuals may still attempt to manipulate measurements.

-

Historical Cases of Fuel Dispenser Fraud:

-

Pulse Signal Interference: Using external devices to interfere with the pulse signals generated by the flow meter, causing it to record less fuel than actually dispensed.

-

Software Tampering: Modifying the internal metering software parameters of the fuel dispenser, such as adjusting the pulse coefficient, to under-measure fuel.

-

Replacing Fraudulent Chips: Installing chips with fraudulent programs on the fuel dispenser's mainboard.

-

Metering Device Adjustment: Illegally adjusting the calibration screws of the metering device to alter measurement parameters.

-

Pre-setting Fraudulent Volumes: Pre-setting a fraudulent volume before fueling, after which the dispenser automatically reverts to normal measurement.

-

Manipulating Temperature Compensation: Deliberately disabling or modifying temperature compensation settings in cold weather, leading to measurement based on the volume of colder fuel, while the actual volume of warmer fuel dispensed is greater (or vice-versa).

-

-

How Regulators Combat "Fuel Theft" and Countermeasures:

-

Unannounced Inspections and Covert Visits: Market supervision departments conduct regular or irregular inspections of gas stations, including on-site comparisons using standard measuring instruments.

-

Technological Upgrades and Anti-Tampering Measures: Promoting the use of electronic flowmeters with higher security levels, stronger anti-tampering features, and encrypted software.

-

Remote Monitoring Systems: Some regions have introduced remote monitoring systems for fuel dispensers, which continuously track their operational status and measurement data, alerting authorities to any anomalies.

-

Whistleblower Reward Mechanisms: Encouraging consumers to report fraudulent activities and offering rewards.

-

Blockchain for Tamper-Proof Records: Emerging technology that leverages the immutability of blockchain to record every fueling transaction, enhancing transparency and trustworthiness.

-

-

Case Study: Why Some Countries Sell Fuel by Mass (Kilograms) Instead of Volume (Liters):

-

Some countries (e.g., parts of Brazil and Indonesia) choose to sell fuel by mass rather than volume primarily to eliminate errors caused by temperature variations affecting volumetric measurement. The volume of fuel expands or contracts with temperature changes (thermal expansion and contraction), but its mass remains constant regardless of temperature. Selling by mass avoids measurement disputes caused by temperature fluctuations, ensuring consumers pay for the exact mass of fuel.

-

4. Factors Affecting Fuel Flow Meter Accuracy

The accuracy of fuel flow meters is influenced by various factors.

-

Impact of Temperature Changes on Fuel Volume Measurement:

-

Thermal Expansion and Contraction: The volume of fuel (especially gasoline and diesel) expands as temperature rises and contracts as temperature falls. In hot weather, if fuel is measured by volume, consumers might receive expanded fuel, which will have slightly less actual mass; conversely, in cold weather, they might receive a smaller volume of fuel, but with slightly more mass.

-

Automatic Temperature Compensation (ATC): To address this, many modern fuel dispensers are equipped with temperature compensation systems. These systems use built-in temperature sensors to continuously measure fuel temperature and convert the actual volume to the equivalent volume at a standard temperature (e.g., 15°C or 20°C) using a pre-set expansion coefficient, ensuring fair measurement.

-

-

Measurement Deviations Due to Equipment Aging, Wear, or Improper Maintenance:

-

Mechanical Component Wear: Over long-term use, mechanical components of positive displacement flowmeters like pistons and rotors can wear out, increasing internal clearances and potentially leading to measurement deviations (usually under-measurement).

-

Filter Clogging: Clogged filters in the nozzle can affect the stability of the fuel flow, thereby impacting the accuracy of the flow meter.

-

Seal Aging: Aging seals can lead to internal leaks, causing the actual amount of fuel passing through the flow meter to be less than the recorded amount.

-

Calibration Deviation: If a gas station does not regularly calibrate its flow meters or calibrates them improperly, it can also lead to inaccurate measurements.

-

5. How Consumers Can Verify Fueling Accuracy

Consumers can take steps to verify fuel volume and file complaints if they encounter disputes.

-

Simple Self-Verification Methods:

-

Comparing with Vehicle Tank Capacity: Know your vehicle's stated fuel tank capacity. If the amount of fuel dispensed significantly exceeds this capacity when the tank is almost empty, there might be a measurement issue. However, note that tanks are never completely empty and have safety reserves, so this is only a rough estimate.

-

Third-Party Measuring Tools: In some permissible regions, consumers can bring their own verified standard measuring devices (e.g., a 20-liter standard can) to the gas station for on-site comparison. This typically requires the gas station's cooperation.

-

Observing the Fueling Process: Ensure the nozzle is fully inserted into the tank to avoid inaccurate measurements caused by premature auto-shutoff or excessive foaming.

-

-

How to File a Complaint with Market Regulation Authorities in Case of a Measurement Dispute:

-

Retain Evidence: Keep your fuel receipt, noting the dispenser number, fueling time, amount, and volume.

-

Take Photos: Photograph the dispenser's display screen, verification label, and seals.

-

Communicate Directly with the Gas Station: First, try to discuss the situation with the gas station staff.

-

Contact Market Regulation Authorities: If communication is ineffective or you suspect fraudulent activity, immediately call your local market supervision and administration department's complaint hotline (e.g., 12315 in China). Provide detailed information and evidence; the regulatory department will dispatch personnel for on-site verification.

-

6. New Technologies in Fuel Measurement

As technology advances, new innovations are being applied to enhance the accuracy and security of fuel measurement.

-

Development of Smart Fuel Flow Meters:

-

Internet of Things (IoT) Real-time Monitoring: Smart flow meters can integrate IoT modules to upload real-time measurement data and equipment operational status to a cloud platform. Regulators and gas stations can remotely monitor and detect anomalies promptly.

-

Blockchain for Tamper-Proof Records: Leveraging blockchain's distributed ledger technology, every fueling transaction can be encrypted and uploaded to the blockchain, ensuring data immutability and enhancing transparency and trustworthiness.

-

Artificial Intelligence (AI) for Predictive Maintenance: By analyzing flow meter operational data, AI can predict potential equipment failures and wear, allowing for proactive maintenance and preventing measurement deviations.

-

-

Trend of Combining Contactless Payment with Accurate Measurement:

-

With the rise of mobile payment and license plate recognition technologies, fuel measurement will also be deeply integrated with these innovations. Future fueling experiences are likely to be more convenient, while backend data linkage and intelligent algorithms will further enhance measurement precision and anti-fraud capabilities.

-

7. Maintenance and Calibration of Fuel Flow Meters

Regular maintenance and calibration are crucial for ensuring the accuracy of fuel flow meters.

-

How Gas Stations Regularly Maintain Flow Meters to Ensure Accuracy:

-

Daily Inspections: Gas station staff should daily check the fuel dispenser's appearance, display screen, and seals for integrity, and look for any leaks in the nozzle and hose.

-

Filter Cleaning: Regularly clean the filters in the nozzle and before the metering device to prevent clogging that could affect fuel flow.

-

Component Inspection and Replacement: Periodically inspect the internal wear of the metering device and replace wear-prone parts, such as seals and piston rings, according to the manufacturer's recommendations.

-

Environmental Maintenance: Keep the area around the fuel dispenser clean to prevent dust and debris from entering the metering system.

-

-

Calibration Cycles and Procedures: Why Third-Party Involvement is Necessary:

-

Calibration Cycle: According to metrological regulations in most countries, fuel dispensers typically require mandatory verification (calibration) annually. Recalibration is also necessary after major repairs or relocation.

-

Calibration Procedure: Professional metrological verification personnel use standard measuring instruments (such as standard metal provers) to compare and measure the fuel dispenser's readings. They follow strict procedures to conduct multiple tests, ensuring that the fuel dispenser's indicated error is within the permissible range at various flow rates.

-

Why Third-Party Involvement?: Third-party metrological verification institutions possess independence, professionalism, and authority. They are equipped with certified standards and professional personnel to conduct fair and accurate verification of fuel dispensers according to national standards, avoiding potential conflicts of interest and technical irregularities that could arise from self-calibration by gas stations, thereby protecting consumer rights.

-

8. Impact of Electric Vehicles on Fuel Measurement

The rise of electric vehicles is profoundly impacting the traditional fuel measurement market.

-

Is Demand for Gas Station Flow Meters Declining?

-

As electric vehicle sales continue to grow, the growth rate of traditional internal combustion engine vehicle ownership will slow down and may even decline at some point in the future. This will directly lead to a decrease in demand for fuel, consequently affecting the number of gas stations and the market demand for fuel flow meters. Flow meter manufacturers may need to adjust their business strategies, shifting towards other fluid metering fields or electric vehicle charging measurement.

-

-

Will Fuel Measurement Technology Be Completely Replaced by Electrical Energy Measurement in the Future?

-

In the foreseeable future, fuel-powered vehicles will continue to exist for a significant period, so fuel measurement technology will not completely disappear. However, electrical energy measurement will become increasingly important in charging stations and for electric vehicles, potentially eventually becoming dominant. The future energy measurement market will likely see a coexistence of fuel measurement and electrical energy measurement, though the focus may gradually shift towards electrical energy.

-

9. Environmental Protection and Fuel Measurement

Accurate measurement is also closely linked to environmental protection.

-

How Accurate Measurement Reduces Fuel Waste and Carbon Emissions:

-

Waste Reduction: Precise measurement prevents excessive fueling or waste due to inaccurate readings, leading to more efficient use of finite resources.

-

Optimized Management: Accurate measurement data helps gas stations and transportation companies better manage fuel inventory and consumption, reducing environmental risks like spills and leaks.

-

Promoting Energy Efficiency: When consumers have clear expectations for fuel volume, they become more conscious of their vehicle's fuel efficiency, thus encouraging them to adopt more fuel-efficient driving habits or vehicles, indirectly reducing carbon emissions.

-

-

Challenges of Biofuels (e.g., Ethanol Gasoline) for Traditional Flow Meters:

-

Material Compatibility: Biofuels, especially high-blend ethanol gasoline, can corrode or swell the rubber and plastic sealing materials in traditional fuel flow meters, leading to equipment damage or inaccurate measurements.

-

Viscosity and Density Differences: The viscosity, density, and rheological properties of biofuels may differ from traditional gasoline or diesel, which can affect the accuracy of some volume-based or turbine-based flow meters.

-

Calibration Standards: For mixed fuels containing biofuels, new or adjusted measurement calibration standards are required to accommodate their changing properties. Therefore, specifically designed or modified flow meters are needed to accurately measure biofuels.

-